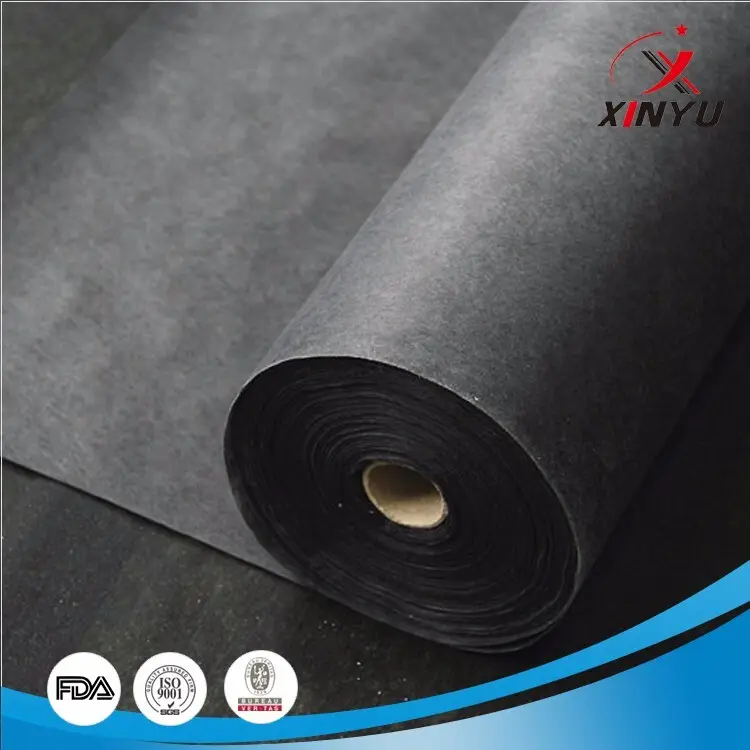

Brand Explains Seamless Woven Fusible Interlining

Seamless woven fusible interlining is a fabric technology that joins multiple layers of fabric together with minimal or no seams, resulting in a smooth, undetectable transition. This technology is widely used in industries such as apparel, footwear, aerospace, and packaging. Unlike traditional interlinings, which require stitching or heatsetting, fused interlinings are inherently seamless, enhancing performance and comfort.

How Woven Fusible Interlining Works

The process of creating a woven fusible interlining involves several steps. First, raw materials like polyester, cotton, or nylon are woven into layers. These layers are then bonded together using heat-set adhesives, which fuse the fabric without the need for seams. The resulting fabric is durable, lightweight, and highly resistant to wear and tear. The seamless design ensures a natural fit, making it ideal for applications where breathability and durability are crucial.

Benefits of Seamless Woven Fusible Interlining

The benefits of using seamless woven fusible interlining are manifold. It enhances the performance of garments by improving flexibility, durability, and weather resistance. The seamless design also reduces the risk of discomfort caused by seams, making it particularly suitable for sensitive skin. Additionally, the technology allows for greater design flexibility, enabling brands to experiment with innovative shapes and patterns. Its environmental impact is also noteworthy, as it reduces pollution from traditional stitching methods.

The Manufacturing Process of Seamless Woven Fusible Interlining

Steps Involved in Production

The manufacturing process of seamless woven fusible interlining begins with raw material preparation. High-quality fibers are selected based on their properties, such as tensile strength and breathability. These fibers are then woven into multiple layers using modern textile machinery. The layers are carefully aligned to ensure precision and consistency.

Next, the layers are bonded together using heat-set adhesives. These adhesives are designed to fuse the fabric at a high temperature, ensuring a strong and durable bond. The process is automated to maintain quality and efficiency. Quality control measures are implemented at every stage to ensure the final product meets stringent standards.

Key Materials and Quality Control

The choice of materials is critical in the manufacturing process. High-quality fibers like polyester and nylon are used for their durability, while organic cotton is preferred for its environmental sustainability. The production process is monitored closely to ensure consistency in tensile strength, density, and colorfastness. These parameters are essential for achieving the seamless and fused effect.

Environmental considerations are also addressed during production. Recycled materials are incorporated where possible to reduce the carbon footprint. The use of eco-friendly adhesives and energy-efficient machinery further contributes to sustainable manufacturing practices.

Design Advantages and Applications in Fashion

Enhancing Fit and Comfort

Seamless woven fusible interlining offers significant advantages in terms of fit and comfort. The absence of seams eliminates pressure points and provides a smooth transition between layers, making it ideal for tight-fitting garments. This feature is particularly beneficial for active wear, where breathability and durability are key.

Design Flexibility

The design flexibility of seamless interlining allows brands to experiment with innovative shapes and patterns. It enables the creation of complex geometries that would be impossible with traditional interlinings. This flexibility has led to the development of unique and stylish garments, from flowing dresses to functional outerwear.

Case Studies

Several fashion brands have successfully incorporated seamless woven fusible interlining into their designs. Patagonia, for instance, uses it in its hiking and outdoor apparel to enhance performance and durability. Adidas has also embraced this technology to create lightweight, breathable sports apparel. These case studies highlight the versatility and potential of seamless interlining in the fashion industry.

Environmental Impact and Sustainable Practices

Current Environmental Impact

Traditional interlinings often require stitching, which can produce toxic fumes and waste. The seamless woven fusible interlining technology eliminates this issue, reducing pollution and waste. Additionally, the use of high-quality, eco-friendly materials minimizes the environmental footprint of the final product.

Sustainable Practices

Sustainable manufacturing practices are integral to the production of seamless woven fusible interlining. The use of recycled materials, organic fibers, and energy-efficient machinery reduces the environmental impact. The technology also supports circular economy principles by minimizing the need for additional raw materials once the product is decomposed.

Eco-Friendly Alternatives

Eco-friendly alternatives to traditional interlinings are increasingly popular. Brands are now offering seamless woven fusible interlining made from recycled materials, reducing waste and environmental harm. These alternatives are gaining traction as consumers demand more sustainable products.

Consumer Feedback and Market Demand Analysis

Consumer Satisfaction

Consumer feedback highlights the numerous benefits of seamless woven fusible interlining. Customers appreciate its breathability, durability, and ability to enhance the fit of their garments. The seamless design is also seen as a sign of quality and innovation, particularly among eco-conscious consumers.

Market Demand

The market for seamless woven fusible interlining is growing rapidly. There is a high demand for durable, lightweight fabrics in both apparel and industrial applications. The increasing popularity of active wear and sustainability initiatives is driving the adoption of this technology.

Future Trends

The future of seamless woven fusible interlining looks promising. Advances in material science and manufacturing technology are expected to push the boundaries of what is possible. Innovations such as multi-layered interlinings and smart fabrics with built-in technology are likely to emerge, opening up new possibilities for design and functionality.

Conclusion

Seamless woven fusible interlining is a revolutionary fabric technology that offers numerous benefits, including enhanced performance, comfort, and environmental sustainability. Its manufacturing process is efficient and relies on high-quality materials and advanced technologies. In the fashion industry, it has opened up new possibilities for design, allowing brands to create innovative and stylish garments. As consumer demand for sustainable and high-quality products continues to grow, seamless woven fusible interlining is poised to play a key role in shaping the future of textiles and fashion.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co