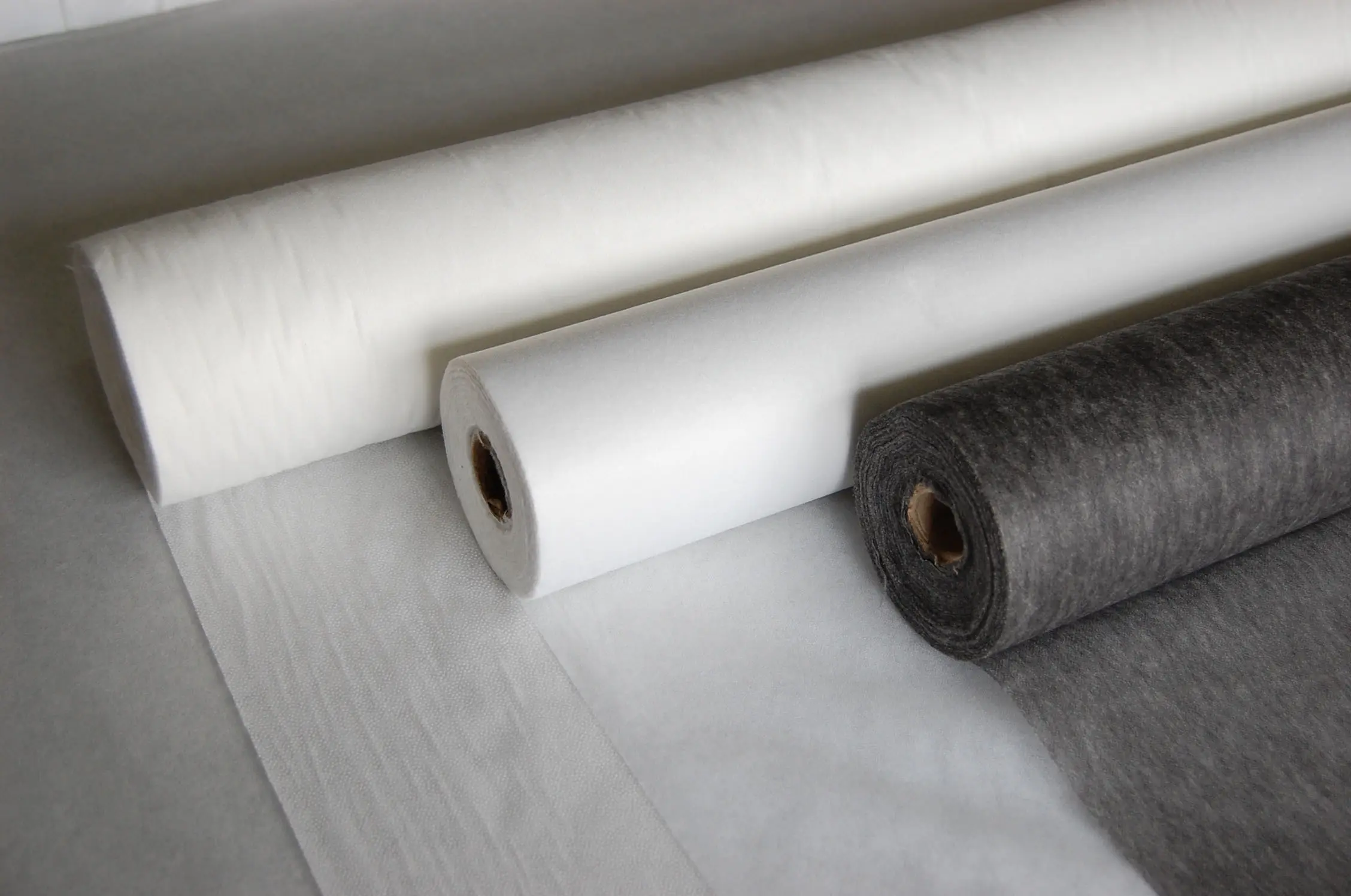

Top Uses of Non Woven Fusible Interlining

Non-woven fusible interlinings have become a staple in the textile industry due to their efficiency and versatility. Typically made from fibers like polyester, these interlinings offer excellent durability and ease of application, making them ideal for a wide range of garments. As technology advances, there is a growing emphasis on sustainability, leading to the development of eco-friendly materials such as recycled polyester and blended natural fibers. These innovations enhance the environmental performance of the interlining, improving breathability and moisture management while aligning with industry best practices. Certifications like GOTS and OEKO-TEX ensure consistency and transparency in the supply chain, supporting sustainable manufacturing processes. The seamless integration of these materials enhances both performance and consumer appeal, making them a key consideration for designers and manufacturers looking to meet both environmental and quality standards.

Applications of Non Woven Fusible Interlining in Fashion Design

Non-woven fusible interlinings enhance the stability and structure of various garments, making them a critical tool in fashion design. They are especially effective in lightweight fabrics like silk and chiffon, where maintaining shape and drape is crucial. These interlinings are particularly useful in jackets, blazers, delicate dresses, and tailored trousers, ensuring the desired fit and silhouette without adding bulk. In performance-based clothing, such as dancewear and athletic wear, non-woven fusibles provide necessary support to enhance wearability and functionality. For instance, they help chiffon dresses maintain their elegant drape and ensure dance leotards stay form-fitting through rigorous rehearsals. Additionally, these interlinings are essential for creating complex design elements like peekaboo hems and intricate pleats by providing the internal support needed for these delicate features. In sustainable fashion, eco-friendly options are increasingly adopted to reduce the environmental impact while maintaining necessary structural integrity, supporting broader sustainability goals in the industry.

Benefits of Using Non Woven Fusible Interlining

Non-woven fusible interlinings offer numerous benefits, making them a preferred choice for garment manufacturers. Enhanced stability and shape retention ensure garments maintain their desired fit and shape over time, particularly in structured garments like coats and jackets. Improved wear resistance extends the life of the garment, reducing wear and tear, especially with frequent washing and regular use. These interlinings are user-friendly, requiring no complicated sewing steps, simplifying the garment-making process and reducing waste. Lightweight and breathable, they add support to light fabrics without adding bulk, allowing for crisp, polished finishes while maintaining fabric breathability. Versatile in garment construction, they can be used in various types of clothing, from dresses and blouses to outerwear, offering flexibility in achieving specific design aspirations.

Types of Non Woven Fusible Interlinings

Non-woven fusible interlinings come in different types, each with distinct attributes:

1. Polyester - Known for its strength and stability, polyester is ideal for tailored garments like dresses and coats. It provides a sturdy backbone, ensuring a flawless fit with minimal wrinkling.

2. Polyamide - Offers excellent moisture-wicking and breathability, making it a favorite for sportswear. It keeps athletes dry and comfortable during intense workouts by effectively transferring moisture away from the skin.

3. Cellulose - Lightweight and flexible, cellulose is perfect for delicate garments such as blouses and sheer dresses. Its airy and smooth properties enhance drape and feel, creating a pleasant, airy wear experience.

4. Thermally Bonded - Combines multiple layers for enhanced structural support, making it a versatile choice for multi-layered garments. Its seamless integration into manufacturing processes delivers noticeable improvements in garment fit and structure.

Each type of non-woven fusible interlining is tailored to specific applications, offering both performance and aesthetic benefits.

Technological Advancements in Non-Woven Fusible Interlining

Technological advancements in non-woven fusible interlinings have transformed the fashion industry by offering a blend of sustainability and performance. These interlinings, made from innovative materials like recycled fibers and biodegradable substances, provide improved thermal regulation, moisture management, and enhanced comfort without compromising style. They are particularly advantageous for high-fashion designs, where intricate patterns and precise fit are required. Laser-cutting techniques and 3D drafting further enhance the integration of these interlinings, enabling aesthetic and functional innovation. The industry is fostering a culture of sustainability by adopting recycled materials and promoting transparent supply chains. This shift not only reduces the environmental footprint but also improves labor conditions and product durability, aligning with ethical design practices.

Leading Manufacturers of Non Woven Fusible Interlining

Leading manufacturers of non-woven fusible interlining are increasingly focusing on sustainable practices to meet growing consumer demand. They have introduced biodegradable interlinings made from recycled fibers, which maintain performance standards like drape, durability, and comfort. By optimizing production processes and utilizing advanced technologies, these manufacturers achieve a balance between sustainability and functionality. Collaborative efforts with retailers and consumers play a crucial role in promoting these sustainable practices. For example, consumer education through in-store displays, online platforms, and social media campaigns highlights the environmental benefits and encourages recycling. Engaging suppliers and leveraging blockchain technology for supply chain transparency further enhances the sustainability of these materials. As the industry continues to evolve, manufacturers are exploring innovative recycling processes and after-use solutions to ensure a circular economy.

FAQs Related to Non-Woven Fusible Interlining in Fashion Design

What are the benefits of using non-woven fusible interlining in fashion design?

Non-woven fusible interlinings enhance the stability and structure of various garments, making them a critical tool in fashion design. They are especially effective in lightweight fabrics like silk and chiffon, where maintaining shape and drape is crucial. These interlinings are particularly useful in jackets, blazers, delicate dresses, and tailored trousers, ensuring the desired fit and silhouette without adding bulk. In performance-based clothing, such as dancewear and athletic wear, non-woven fusibles provide necessary support to enhance wearability and functionality.How does non-woven fusible interlining enhance the durability of garments?

Non-woven fusible interlinings enhance the durability of garments by providing enhanced stability and shape retention, which ensures garments maintain their desired fit and shape over time. They also improve wear resistance, extending the life of the garment and reducing wear and tear, especially with frequent washing and regular use.What types of non-woven fusible interlinings are commonly used in fashion?

Non-woven fusible interlinings come in different types, each with distinct attributes. These include polyester, known for its strength and stability; polyamide, which offers excellent moisture-wicking and breathability; cellulose, which is lightweight and flexible; and thermally bonded, which combines multiple layers for enhanced structural support.How do non-woven fusible interlinings improve garment aesthetics?

Non-woven fusible interlinings can improve garment aesthetics by providing support to light and delicate fabrics, helping them maintain a crisp, polished finish. They are particularly useful for creating complex design elements like peekaboo hems and intricate pleats, ensuring these features are supported and look precise. Additionally, eco-friendly options are increasingly adopted to enhance both performance and consumer appeal, supporting broader sustainability goals in the industry.What are the leading manufacturers of non-woven fusible interlining doing to promote sustainable practices?

Leading manufacturers of non-woven fusible interlining are increasingly focusing on sustainable practices by introducing biodegradable interlinings made from recycled fibers. They are optimizing production processes, utilizing advanced technologies, and promoting transparent supply chains. Collaborative efforts with retailers and consumers, such as consumer education through in-store displays and online platforms, and engaging suppliers with blockchain technology for supply chain transparency, play a crucial role in promoting these sustainable practices.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co