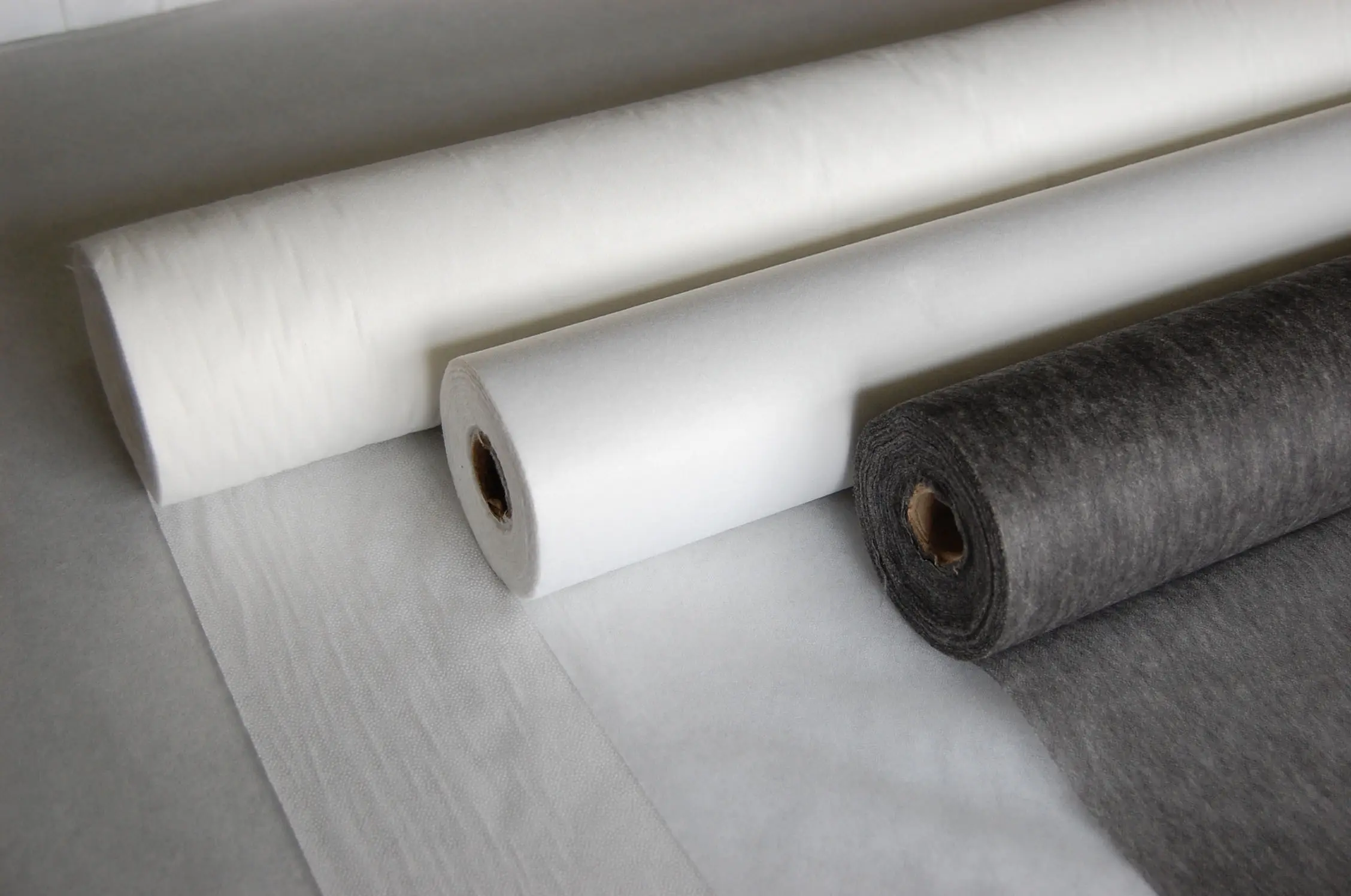

How to Choose Non-Woven Fusible Interlining

Non-woven fusible interlinings offer numerous advantages in textile design, making them a versatile choice for various applications. These interlinings are particularly beneficial due to their:

Versatility: Suitable for use with a wide range of fabric types, including wovens, knits, and delicate materials, ensuring consistent stability across different garment components.

Ease of Application: Iron-on application makes interfacing a simple process, ideal for both mass production and home sewing, reducing the need for complex tools or techniques.

Durability and Longevity: These interlinings provide excellent wear and tear resistance, holding up well through frequent washing and wearing, ensuring a longer garment life.

Sustainability: Made from recyclable materials and offering biodegradable options, they contribute to reducing waste and promoting a more sustainable fashion industry.

Performance: They offer consistent shape retention and stability in tailored garments such as jackets and blazers, enhancing the overall quality and fit of clothing items.

Types of Non-Woven Fusible Interlining and Their Applications

Non-woven fusible interlinings come in various types, each designed to suit specific applications:

Rayon: Known for its soft, flowy drape, rayon is ideal for garments like blouses and dresses, providing a light and elegant touch.

Polyester: Offers excellent sturdiness, making it perfect for jackets and coats, ensuring structure and durability.

Recycled Polyester: Provides durability and washability while reducing environmental impact, suitable for various projects from lightweight blouses to structured jackets.

Bamboo: Biodegradable and naturally soft, bamboo is ideal for garments requiring breathability and a natural feel, such as blouses and lightweight tops.

Wool: Adds warmth and a luxurious feel to winter coats and outerwear, providing exceptional insulative properties and a timeless aesthetic.

How to Use Non-Woven Fusible Interlinings in Textile Designing

Using non-woven fusible interlinings in textile designing requires careful consideration of several factors:

- Style and Function: Choose interlining materials based on the garment's intended style and function. For example, polyester interlinings are ideal for structured garments like jackets and coats due to their high strength and washability.

- Testing: Test small samples to assess how the interlining affects the fabric's texture and drape, ensuring the final product meets both functional and aesthetic requirements.

- Rigorous Testing: Utilize drape tests, peel tests, and washability tests to verify adherence and durability, preventing issues like warping or glue residue.

- Balancing Creativity and Practicality: Balancing practical considerations with creativity is crucial for enhancing the overall quality and wearability of the garment.

Comparative Analysis: Non-Woven Fusible Interlining vs. Other Interlinings

Compared to other types of interlinings, non-woven fusibles stand out for their convenience and cost-effectiveness, making them a popular choice in garment construction. However, they have specific limitations:

- Durability: Non-wovens are less durable than woven or knit interlinings, which are more suitable for heavy-duty applications.

- Ease of Use: They are easy to apply and facilitate quicker production cycles, especially for detailed pieces.

- Environmental Impact: Non-wovens produce less waste during cutting but can create more waste at the final product stage, presenting challenges in recycling.

- Cost: They offer initial cost savings and production efficiency, but reduced durability may lead to higher long-term replacement costs.

Careful consideration of these factors helps in selecting the most appropriate interlining for specific garment needs.

Environmental and Sustainable Considerations in Non-Woven Fusible Interlining

To promote sustainability, it is essential to evaluate the environmental impacts of non-woven fusible interlinings throughout their lifecycle. Plant-based and recycled materials offer sustainable alternatives, reducing carbon emissions and resource depletion. However, the transition to these materials requires balancing cost-efficiency, performance, and supply chain challenges.

Developing standardized testing protocols and benchmarks ensures that sustainable materials meet high-performance standards, fostering a transparent and credible market. Engaging stakeholders such as designers, manufacturers, consumers, and policymakers is crucial for driving innovation and implementing closed-loop systems to manage waste effectively.

Choosing the Right Non-Wovens for Your Garment: Key Considerations

When selecting non-woven fusible interlinings, consider the following key factors:

- Fiber Type: Bamboo and cotton offer exceptional breathability and comfort for lightweight garments, while polypropylene ensures longevity and performance in high-wear areas.

- Performance: Different fibers provide unique properties such as warmth, moisture management, and breathability, enhancing both comfort and drape.

- Construction Method: Needle-punching offers flexibility and breathability, making it ideal for lightweight garments, while thermal bonding is cost-effective but may sacrifice some breathability and flexibility.

- Weight and Thickness: Thinner interlinings support the garment's structure without adding bulk, while thicker options enhance rigidity and hold. Selecting the appropriate weight ensures the garment feels well-supported and maintains its shape.

- Sustainability and Cost: Opt for eco-friendly materials like bamboo to reduce environmental impact, but be prepared for potentially higher costs. Implementing sustainable practices, such as bulk ordering and using recycled materials, can offset these increases.

By considering these factors, you can select the most appropriate non-woven fusible interlining to enhance the quality, durability, and sustainability of your garments.

FAQs Related to Non-Woven Fusible Interlinings in Textile Design

What are the key benefits of using non-woven fusible interlining in textile design?

Non-woven fusible interlinings offer versatility, ease of application, durability, sustainability, and performance. They are suitable for a wide range of fabrics, easy to apply, provide consistent stability, are made from recyclable materials, and enhance the fit and quality of garments.What are the different types of non-woven fusible interlinings and how are they used in garment making?

Types include rayon, polyester, recycled polyester, bamboo, and wool. Rayon is used for flowy garments, polyester for structured items, and bamboo for breathable and comfortable pieces. Each material is chosen based on the intended style and function of the garment.How do you use non-woven fusible interlinings in textile designing?

You should choose interlining based on the garment's style and function, test small samples for texture and drape, conduct rigorous testing for adherence and durability, and balance practical considerations with creative design choices to enhance the overall quality and wearability of the garment.What are the advantages and limitations when comparing non-woven fusible interlinings with other interlinings?

Non-woven fusibles are more durable and provide excellent washability and iron-on ease. However, they are less durable than woven or knit interlinings and can produce more waste. While they are cost-effective, the reduced durability may lead to higher long-term replacement costs.How can the environmental and sustainable impact of non-woven fusible interlinings be improved?

Using plant-based and recycled materials, developing standardized testing protocols, engaging stakeholders, and implementing closed-loop systems can reduce environmental impact. Sustainability can be enhanced by balancing cost-efficiency, performance, and supply chain challenges while supporting transparent and credible market practices.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co