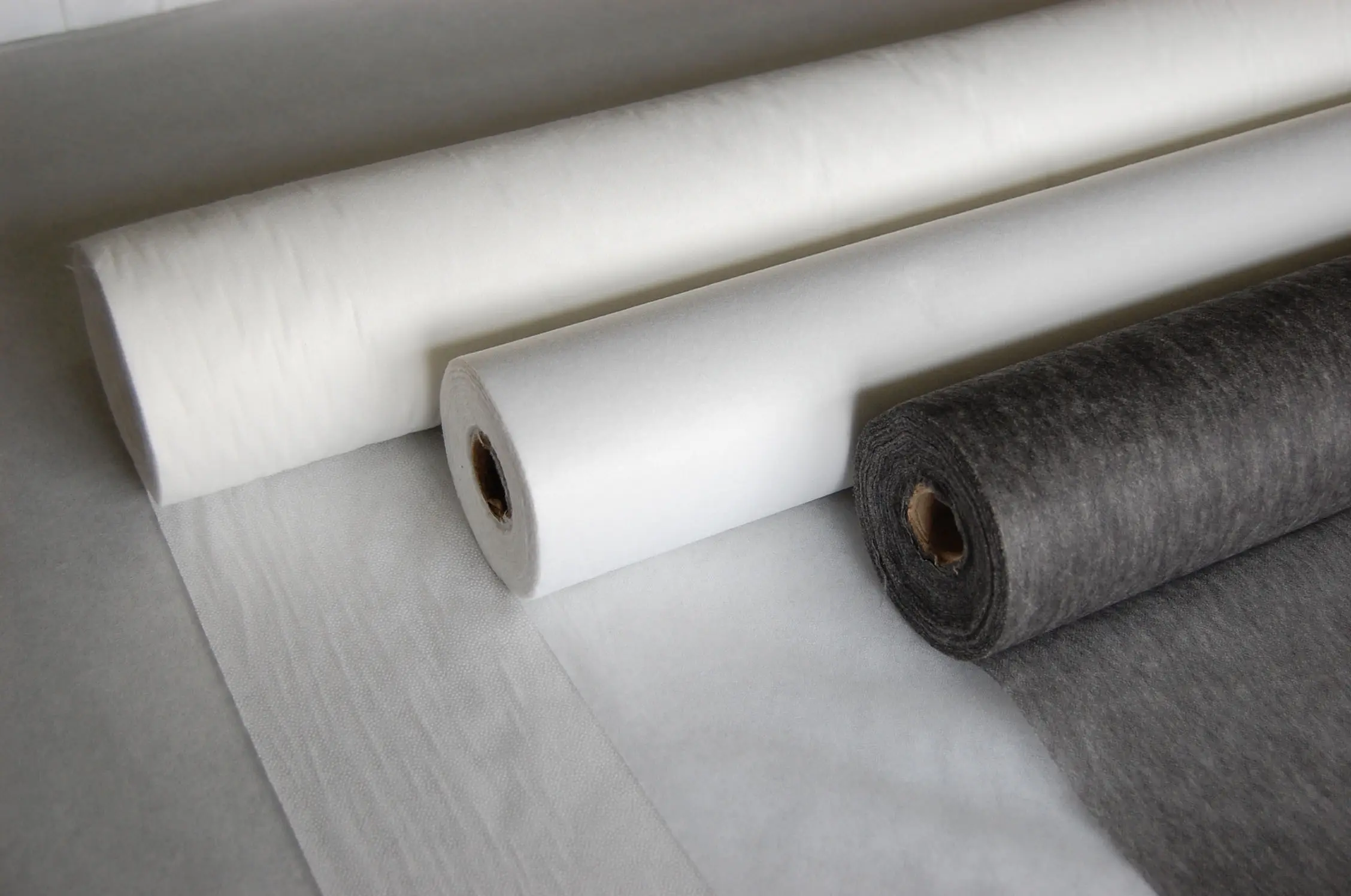

Non Woven Fusible Interlining Fabrics vs Woven Interlinings

Non-woven fusible interlining fabrics seamlessly integrate with garment fabrics, providing a perfect fit that reduces bulk and improves the overall drape and aesthetic of the final product. Their pre-fused nature ensures a cleaner look, while the manufacturing process is faster and less energy-intensive than weaving or knitting. These interlinings are durable yet flexible, thanks to their robust yet pliable base created by combining resin with fibers and heating them. Using organic or recycled fibers, non-woven fusibles also minimize environmental impact, as they require less chemical treatment and lower energy consumption. Moreover, biodegradable and recyclable options contribute to a more sustainable fashion lifecycle, reducing landfill waste and conserving resources.

Properties and Uses of Non-woven Fusible Interlining Fabrics

Non-woven fusible interlinings are known for their lightweight and porous structure, providing excellent breathability and thermal regulation. They can be manufactured using thermal bonding or hot-air laminating techniques, which offer a simpler and faster production process. These properties make them ideal for creating lightweight and comfortable outerwear, enhanced by modern fashion designs that prioritize both style and functionality. In the luxury fashion industry, non-woven fusibles are used to achieve elegant, seamless garments, particularly in high-end clothing where designers seek to enhance comfort and aesthetic appeal. Advanced technologies such as phase-change materials and humidity sensors further expand their applications, adapting garments to different environmental conditions and enhancing both sustainability and performance in luxury fashion.

Manufacturing Process of Non-woven Fusible Interlining Fabrics

The manufacturing process of non-woven fusible interlining involves selecting high-quality fibers such as polyester or polypropylene and blending them to achieve the desired properties. These fibers are bonded using adhesive binders under strict temperature and pressure controls to ensure uniformity. The bonded material undergoes rigorous quality checks, including tensile strength and thermal bonding tests, to ensure performance standards are met. Modern factories leverage automation and digital monitoring systems for predictive maintenance and real-time data tracking, which help in reducing downtime and minimizing waste. These technological advancements improve product consistency and promote more sustainable manufacturing practices by optimizing raw material usage and reducing environmental impact.

Comparative Analysis: Non-woven vs. Woven Interlinings

Non-woven interlinings and woven interlinings each offer distinct advantages in garment construction. Non-woven interlinings are flexible and cost-effective, allowing garments to move naturally while maintaining their shape, making them ideal for outerwear and intricate designs. Woven interlinings, on the other hand, are known for their durability and long-lasting performance, contributing to reduced waste. The choice between the two often depends on specific garment requirements, such as desired drape, stability, and sustainability goals. Non-woven interlinings excel in enhancing the drape and shape of outerwear and complex garments, while woven interlinings provide robust support for structured pieces like tailored suits and blazers.

Environmental Impact of Non-woven Fusible Interlining Fabrics

The environmental impact of non-woven fusible interlinings is a critical area in the sustainability of the textile industry. These materials offer lighter compositions and consume less water and energy compared to their woven counterparts. Life Cycle Assessments (LCAs) have highlighted areas for improvement, such as waste management and chemical usage. Sustainable solutions include mechanical and chemical recycling processes and the use of bio-based or low-VOC binders. Collaborations between industry stakeholders, governments, and research institutions are essential to develop standardized recycling protocols and promote sustainable practices. Integrating renewable energy sources in the manufacturing process can significantly reduce carbon footprints, aligning with broader goals of sustainable design and the circular economy.

Real-World Applications and Success Stories

Non-woven fusible interlinings have demonstrated significant advantages in various garments, enhancing both performance and aesthetics. Notable success stories include their use in lightweight tote bags, where a smooth, crisp finish was achieved despite the delicate nature of the fabric. Practitioners emphasized the importance of proper heat application techniques to avoid scorching, highlighting the need for diligence in initial practice. This approach ensured professional results, highlighting the interlining's ability to maintain structure and drape. Additionally, non-woven fusibles have proven beneficial in high-end spa robes, although careful consideration of washing frequency and environmental conditions is essential. Innovative care solutions, such as low-impact detergents and protective sprays, have effectively extended the lifespan of these interlinings, reducing waste and aligning with sustainable fashion goals. These real-world applications illustrate the versatility and sustainability of non-woven fusible interlinings, offering valuable insights for designers and manufacturers aiming to balance aesthetics with environmental responsibility.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co