Supplier Reputation Matters in Interlining Fabric Selection

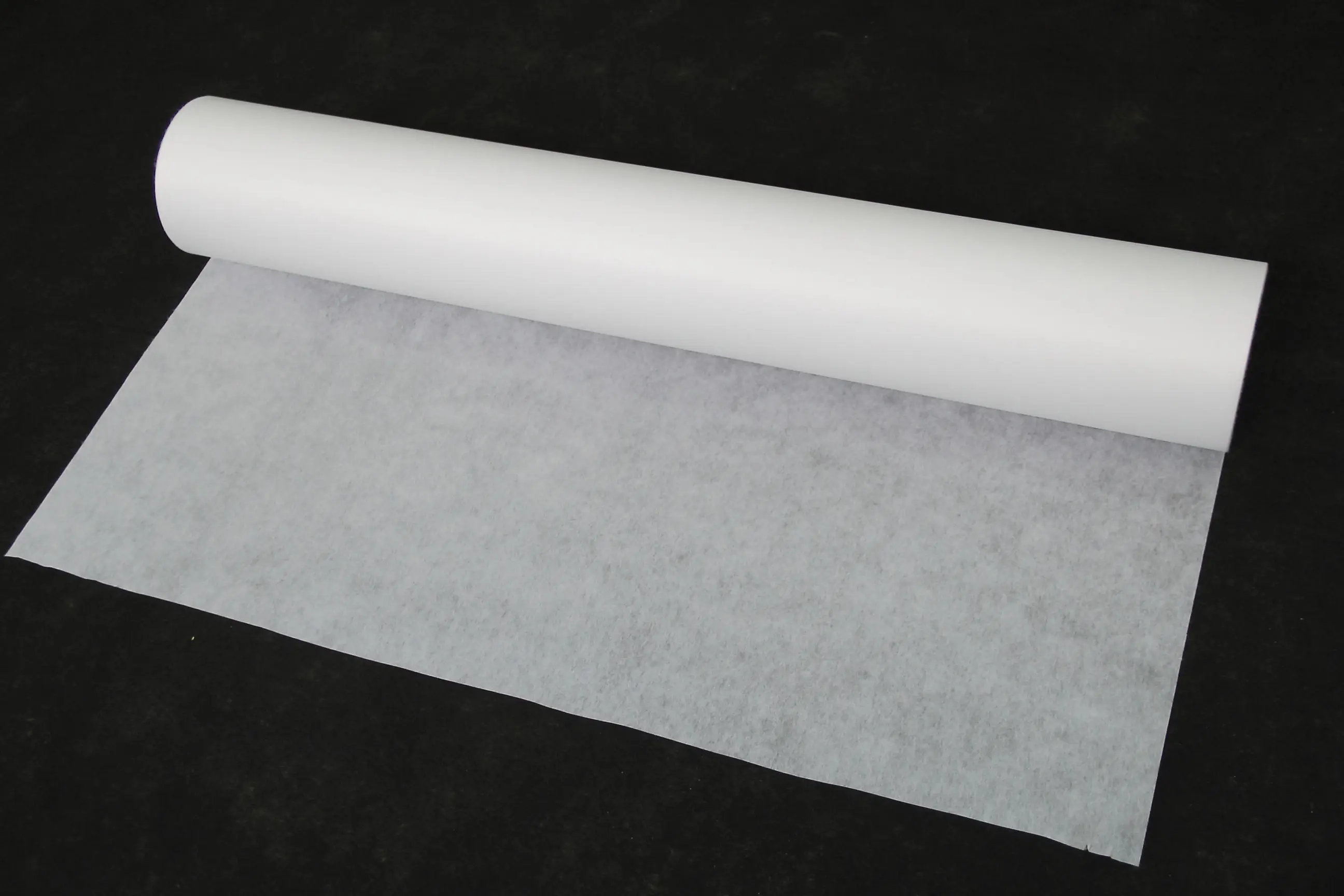

Interlining fabric is a critical component in the production of garments, serving as the material that is placed between the main fabric and the lining of an article of clothing. It plays a vital role in ensuring the comfort, durability, and overall quality of the final product. However, the selection of interlining fabric is not just about finding materials that meet basic standards; it is about choosing high-quality fabrics that align with the companys reputation and customer expectations. Supplier reputation is a crucial factor in the selection process for interlining fabric. A reliable supplier not only provides materials that meet the required specifications but also ensures timely delivery, maintains consistent quality, and provides excellent customer service. When a company works with a supplier with a good reputation, it can expect a long-term partnership built on trust, reliability, and mutual satisfaction.

Key Factors to Consider When Vetting Interlining Fabric Suppliers

Selecting the right interlining fabric supplier involves more than just comparing prices and reviewing product specifications. It requires a comprehensive evaluation of the suppliers reputation and capabilities. Here are some key factors to consider when vetting interlining fabric suppliers:

1. Price and Quality Balance:

While price is an important factor, it is equally important to ensure that the chosen supplier provides high-quality materials that meet the companys standards. A good supplier will offer competitive pricing without compromising on the quality of the interlining fabric. For example, a supplier who sources organic cotton or recycled materials can offer affordable, eco-friendly options that surpass basic quality standards.

2. Delivery Time and Consistency:

Timely delivery is crucial in garment production. A reliable supplier with a history of meeting deadlines will ensure that the interlining fabric arrives when needed, minimizing delays and maintaining production schedules. For instance, a supplier who has a robust logistics network can deliver materials on time, even during peak seasons.

3. Quality Control:

The quality of interlining fabric is paramount, as it directly affects the comfort and durability of the final garment. A reputable supplier will subject the materials to rigorous inspection processes and ensure that they meet international quality standards. For example, a supplier who undergoes third-party audits can provide assurance of quality control.

4. Transparency and Communication:

A transparent and communicative supplier will provide detailed information about the production process, raw material sources, and quality control measures. Open communication helps build trust and ensures that the company has complete visibility into the suppliers operations. For example, regular online meetings or detailed reports can facilitate this process.

5. Customer Testimonials and Industry Recognition:

Customer testimonials and industry recognition are indicators of a suppliers reliability and reputation. Reading reviews from previous clients and checking for awards or accolades can provide valuable insights into the suppliers performance and credibility. For instance, a supplier who has won the Best Supplier of the Year award multiple times demonstrates a strong reputation in the industry.

6. Sustainability and Ethical Practices:

With increasing consumer demand for sustainable and ethically sourced products, it is important to evaluate whether the supplier adheres to environmentally friendly practices and fair labor standards. For example, a supplier who uses organic cotton and fair trade practices not only benefits the environment but also aligns with consumer values.

By considering these factors, companies can shortlist potential suppliers and make an informed decision that aligns with their business goals and values.

Maintaining Long-Term Relationships with Interlining Fabric Suppliers

Building and maintaining strong relationships with interlining fabric suppliers is essential for ensuring the quality, reliability, and sustainability of the supply chain. Here are some strategies for maintaining long-term relationships with suppliers:

1. Regular Communication:

Establishing a culture of open and ongoing communication with suppliers helps to address any issues promptly and ensures that both parties are aligned on goals and expectations. Regular meetings and updates can facilitate this process. For instance, quarterly meetings can be scheduled to discuss progress, challenges, and future plans.

2. Flexibility and Adaptability:

The textile industry is subject to changes in demand, market trends, and supply chain disruptions. A flexible and adaptable supplier can navigate these challenges effectively, ensuring that the interlining fabric supply chain remains resilient. For example, a supplier who can quickly adjust production to meet new demands can help companies maintain their production schedules.

3. Collaboration and Innovation:

Encouraging collaboration between suppliers and companies can lead to innovative solutions and improved efficiency. By working together, both parties can develop new ways to enhance the quality of interlining fabric and reduce costs. For instance, joint development projects can lead to the creation of new, more sustainable interlining materials.

4. Quality Assurance and Continuous Improvement:

A commitment to quality assurance and continuous improvement initiatives can help to maintain a competitive edge in the market. Regular audits and feedback loops can ensure that the supplier is always meeting the highest standards. For example, a supplier who conducts regular internal audits and implements corrective actions can consistently deliver high-quality materials.

5. Trust and Respect:

Building trust and respect with suppliers requires a commitment to ethical practices and mutual respect. Suppliers who prioritize transparency, integrity, and sustainability are more likely to be valued partners in the long term. For example, a supplier who adheres to strict environmental and labor standards can earn the trust of ethical companies and consumers.

By implementing these strategies, companies can foster long-term relationships with interlining fabric suppliers, ensuring a reliable and high-quality supply chain.

Environmental and Ethical Implications of Interlining Fabric Production

The production of interlining fabric has significant environmental and ethical implications, which are increasingly recognized by consumers and industries alike. Companies that prioritize sustainability and ethical sourcing are better positioned to meet the growing demand for eco-friendly and ethically produced goods. Here are some key points:

Environmental Impacts of Interlining Fabric Production

The production of interlining fabric involves several environmental challenges, including water usage, energy consumption, and the potential use of harmful chemicals. For example, the dyeing and printing processes used in fabric production can release toxic substances into water bodies, contributing to pollution. Additionally, the extraction of raw materials, such as cotton, can have a significant environmental impact due to deforestation and water scarcity.

Consumers are increasingly aware of the environmental impact of their purchases and are demanding greater transparency from companies. By selecting sustainable and eco-friendly interlining fabrics, companies can reduce their environmental footprint and contribute to global sustainability efforts. For instance, using organic cotton or recycled materials can significantly lower the environmental impact of fabric production.

Ethical Sourcing Practices

Ethical sourcing practices, such as fair labor practices and sustainable material use, are essential for ensuring that workers are treated humanely and that the environment is protected. Interlining fabric production should adhere to international labor and environmental standards, such as those outlined by the Global Organic Textile Initiative (GOTS) and the Fair Trade Organization. For example, ensuring that workers are paid fairly and working in safe and healthy conditions can improve both social and environmental outcomes.

Fair labor practices involve ensuring that workers are paid in a timely manner, working in safe and healthy conditions, and having access to adequate benefits. Sustainable material use involves minimizing the environmental impact of the production process by using recycled materials, reducing water and energy consumption, and avoiding the overuse of harmful chemicals.

By adopting ethical sourcing practices, companies can build trust with their customers and align with their values. Ethical interlining fabric production not only benefits the workers but also contributes to a healthier planet for future generations.

Choosing Sustainable and High-Quality Interlining Fabrics

Selecting sustainable and high-quality interlining fabrics is a critical step in ensuring the environmental and ethical implications of the production process are minimized. Here are some criteria for choosing sustainable interlining fabrics and case studies of successful implementations:

1. Sustainable Material Selection:

Look for interlining fabrics that are made from sustainable materials, such as organic cotton, recycled polyester, or recycled materials. These materials not only reduce the environmental impact of fabric production but also align with consumer demand for eco-friendly products. For example, a supplier who uses recycled polyester can offer durable, long-lasting options with a lower environmental footprint.

2. Fair Labor Practices:

Ensure that the supplier adheres to fair labor practices, such as ensuring that workers are paid in a timely manner, working in safe and healthy conditions, and having access to adequate benefits. For instance, a supplier who is certified by the Fair Trade Organization can provide assurance of fair labor practices.

3. Closed-Loop Production:

Closed-loop production involves collecting and recycling by-products from fabric production, such as trimmings and leftovers, to reduce waste and minimize the environmental impact of the process. For example, a supplier who uses a system to recycle leftover materials can significantly reduce waste and improve sustainability.

4. Case Studies of Successful Implementations:

Many companies have successfully implemented sustainable interlining fabric production by collaborating with suppliers who adhere to ethical and environmental standards. For example, Patagonia, a leading outdoor apparel company, has worked with suppliers who use recycled materials and adopt closed-loop production processes to minimize their environmental footprint. By prioritizing sustainability, they can provide high-quality, eco-friendly options that meet customer expectations.

Conclusion

Supplier reputation plays a pivotal role in the selection of interlining fabric, as it directly impacts the quality, reliability, and sustainability of the final product. By considering factors such as price, delivery time, quality control, transparency, customer testimonials, and sustainability, companies can shortlist suppliers and make informed decisions that align with their business goals and values.

Maintaining long-term relationships with interlining fabric suppliers is essential for ensuring a reliable and high-quality supply chain. Strategies such as regular communication, flexibility, and collaboration can help to build trust and strengthen partnerships.

Moreover, the environmental and ethical implications of interlining fabric production must not be overlooked. By selecting sustainable and ethically sourced materials, companies can reduce their environmental impact and contribute to a healthier planet.

In conclusion, supplier reputation is crucial in ensuring the quality, reliability, and sustainability of interlining fabric. By prioritizing these factors, companies can enhance their reputation, meet customer expectations, and drive long-term success in their supply chain.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co