Enhance Garments with Expert Interlining Fabric

Interlining fabric is a crucial element in garment manufacturing, often the unsung hero that transforms ordinary clothing into comfy, durable, and stylish wear. This hidden layer, sandwiched between the main fabric and lining, plays a pivotal role in enhancing comfort, durability, and overall performance. In the fashion and textile industries, interlining is a fundamental technique that ensures clothing not only looks great but also performs exceptionally well, withstands wear and tear, and is a joy to wear in various conditions. Whether you're crafting a cozy winter sweater or designing a vibrant summer dress, interlining can make all the difference.

Latest Advancements in Interlining Technology

The fashion and textile industries are constantly pushing the boundaries of innovation, driven by the demand for sustainable and high-performance solutions. Recent advancements in interlining fabric have introduced groundbreaking techniques and materials that have transformed the way garments are made. One of the most versatile methods is heat-fusing, which involves the use of irons or welding machines to bond the interlining to the garment at a precise temperature. This method ensures a strong, durable bond, making it particularly effective for synthetic fabrics.

Another innovative technique is ultrasonic fusing, which uses high-frequency sound waves to achieve superior adhesion without the need for high temperatures. This method not only reduces energy consumption and environmental impact but also preserves the integrity of delicate fabrics and intricate designs. Additionally, chemical bonding offers a versatile solution with water-based or solvent-based adhesives. These adhesives are designed to withstand various environmental conditions, making them suitable for a wide range of applications.

Techniques for Effective Interlining

Achieving a perfect bond is crucial for ensuring the longevity and comfort of interlined garments. Here are some key techniques to consider:

- Heat Fusing: Involves heating the interlining and garment to a specific temperature using irons or welding machines. Consistent temperature and pressure are crucial for a strong bond, particularly for synthetic fabrics.

- Ultrasonic Fusing: Uses high-frequency sound waves to create microscopic vibrations in the fabric, promoting adhesion without the risk of warping the garment. This method is ideal for delicate fabrics and intricate designs.

- Chemical Bonding: Offers a versatile solution with water-based or solvent-based adhesives. These adhesives are designed to withstand various environmental conditions, making them suitable for a wide range of applications.

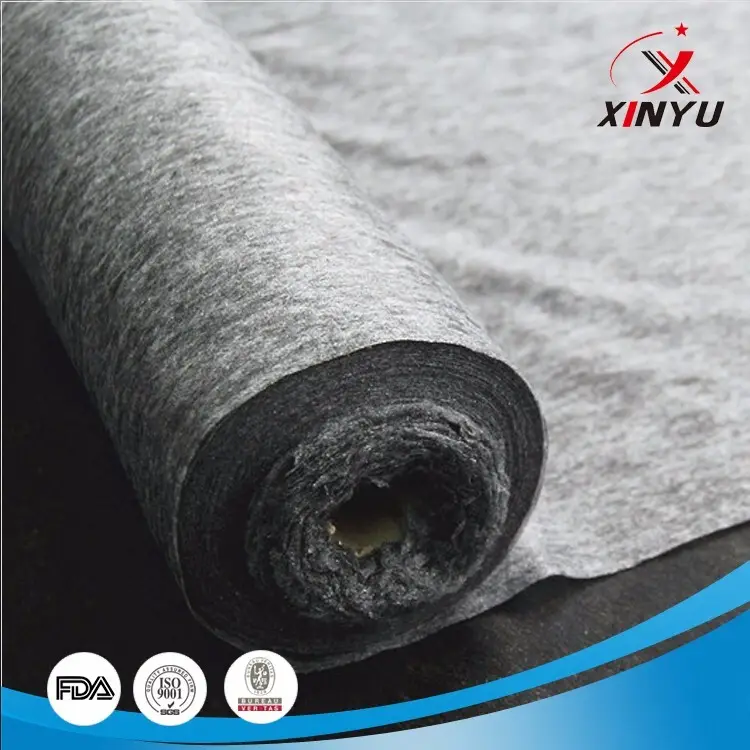

Types of Interlining Materials

Choosing the right interlining material is crucial for achieving the desired outcome. Here are the most common types:

- Natural Fabrics: Such as cotton and wool, known for their breathability and softness, making them ideal for casual wear. However, they may not be as durable in harsh weather conditions.

- Synthetic Materials: Including polyester and nylon, these are favored for their strength and durability, making them excellent for activities like hiking and sports.

- Polyurethane Interlining: Known for its water resistance, this material is a top choice for outdoor clothing.

- Eco-Friendly Materials: Plant-based fabrics and recycled materials are increasingly available, reducing the environmental footprint and catering to consumers who prioritize sustainability.

Sustainable Interlining Options

Sustainability is a cornerstone of modern fashion. Eco-friendly interlining options, such as plant-based fabrics and recycled materials, are transforming the industry. These materials not only minimize environmental harm but also align with consumer preferences for ethically produced goods. By adopting sustainable practices, manufacturers can reduce waste, lower carbon emissions, and promote a more responsible approach to garment production. Whether you're looking to make a positive environmental impact or simply meet the demands of conscious consumers, eco-friendly interlining is a must-consider option.

Effects on Product Quality, Durability, and Finish

The use of interlining fabric has a profound impact on the quality, durability, and finish of garments. Interlining enhances durability by adding an extra layer, protecting the garment from wear and tear, especially in high-traffic areas. It also improves comfort by regulating temperature and moisture, ensuring that garments are a joy to wear. The finish of the interlining, whether smooth or textured, can elevate the garment's appearance, adding a unique touch that sets it apart.

Summary and Reflection

To summarize, expert interlining fabric is a vital component in garment manufacturing, offering a multitude of benefits from enhanced durability to improved comfort. With advancements in technology and a growing emphasis on sustainability, manufacturers are empowered to create garments that not only perform well but also align with environmental and ethical standards. By exploring the latest techniques, selecting appropriate materials, and considering the impact on product quality, the industry can continue to innovate and deliver high-quality garments that resonate with consumers. Embracing the expertise of interlining fabric ensures that garments are not only stylish but also built to last, making them a timeless and reliable choice for wearers.

Embrace the power of expert interlining fabric to elevate your garment manufacturing game. Whether you're a seasoned fabricator or a budding designer, understanding and utilizing interlining fabric can set your products apart and make a significant impact on the way people perceive and use clothing.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co