How Are Pet Nonwoven Fabrics Made and What Makes Them Special?

Pet nonwoven fabrics are a popular choice for pet products due to their durability, hypoallergenic properties, and ease of maintenance. These fabrics are engineered through advanced processes such as spunbonding and meltblowing, creating uniform webs of fibers that are subsequently bonded using thermal, chemical, or mechanical methods. Consequently, pet nonwoven fabrics are prized for their strength, hypoallergenic nature, and ease of cleaning, being especially beneficial for pet bedding, clothing, and hygiene products. Pet owners appreciate the reduced matting, shedding, and simple cleaning routines offered by these materials. Additionally, nonwoven fabrics can be made from eco-friendly materials like recycled polyester and bio-based fibers such as hemp and bamboo, making them an environmentally sustainable option. Innovations such as sensor integration offer enhanced functionality by monitoring pet health parameters, such as temperature and moisture levels, which aids in early detection of health issues and improved recovery.

Unique Properties of Pet Nonwoven Fabrics

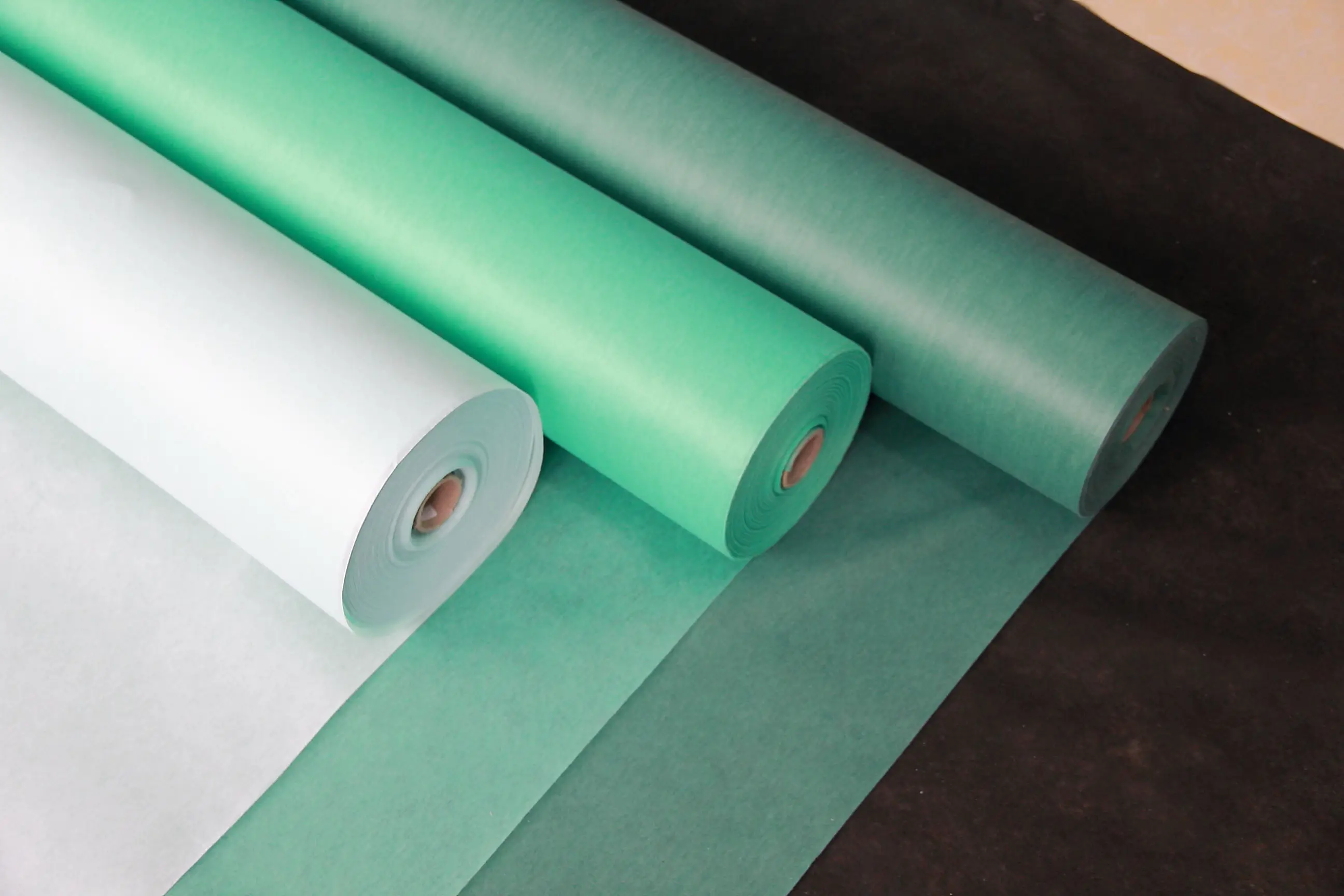

Pet nonwoven fabrics stand out due to their unique properties, especially when made from polyethylene terephthalate (PET). PET nonwovens benefit from high melting temperatures, excellent chemical resistance, and durability, making them ideal for applications that require longevity and performance in harsh conditions. Recent advancements have introduced biodegradable PET derivatives and nano-bonding techniques to further enhance their sustainability and strength. Additionally, the integration of microfibers contributes to a softer, more breathable fabric, making PET nonwovens particularly suitable for various industries, including pet care, where they are valued for their water resistance, stain resistance, and eco-friendly attributes.

Production Process of Pet Nonwoven Fabrics

The production of PET nonwoven fabrics involves several key steps designed to balance efficiency and quality. Initially, polyester resin is melted and extruded into filaments, which are then spun, textured, and stretched to enhance strength and flexibility. These filaments are randomly deposited on a moving conveyor belt using air or mechanical methods to form a web. Bonding techniques, such as thermal, ultrasonic, or chemical methods, are then applied to increase the fabric's strength and integrity. Innovative thermoplastic materials have been introduced to improve thermal stability and flexibility, while ultrasonic bonding offers significant environmental benefits by reducing energy consumption and eliminating chemical adhesives.

Applications of Pet Nonwoven Fabrics

Pet nonwoven fabrics, particularly those made from recycled PET, have versatile applications in pet care products. These fabrics effectively manage odors and control shedding, making them suitable for pet beds, blankets, and clothing. Recycled PET nonwovens are also used in pet cleaning wipes and towels, providing enhanced cleaning efficacy while being easy to clean and reuse. These materials contribute to environmental sustainability by reducing plastic waste and conserving resources. Integrated with natural ingredients like lavender, they offer a soothing touch beneficial for pets. Innovations like the incorporation of silver ions further enhance their antibacterial properties, making them ideal for pet hygiene products.

Advantages of Nonwoven Fabrics for Pet Care Products

Nonwoven fabrics are highly advantageous in pet care products for their superior absorbency, strength, and breathability. Their quick and effective moisture management ensures efficient cleaning and odor control. Their durability makes them perfect for wearable items such as harnesses, beds, and carriers, ensuring long-lasting performance. Breathability is crucial in providing a comfortable environment while preventing heat and humidity buildup, which can cause skin irritation. Nonwoven fabrics' hypoallergenic properties make them suitable for pets with sensitive skin, reducing the risk of allergic reactions. Customizability allows the integration of antimicrobial agents to prevent infections and odors, making nonwovens ideal for hygiene products.

Raw Materials and Sustainability in Pet Nonwovens

In the pet nonwovens industry, raw materials are crucial for sustainability. Biodegradable PET derived from recycled plastic bottles significantly reduces environmental waste and energy consumption. Plant-based plastics made from renewable resources like corn starch or sugarcane offer a sustainable alternative to conventional petroleum-based plastics. Closed-loop recycling systems capture waste from manufacturing processes and turn it back into a valuable resource for new pet nonwovens. Bio-based adhesives and binders, such as those derived from soy or wheat, minimize environmental impact while maintaining product strength. Investing in state-of-the-art manufacturing equipment and converting to renewable energy sources further reduces energy consumption and carbon emissions, ensuring sustainable production practices.

These enhancements and sustainable practices make pet nonwoven fabrics not just durable and effective, but also environmentally responsible, aligning with the growing demand for eco-friendly pet care solutions.

FAQs Related to Pet Nonwoven Fabrics

What are the unique properties of pet nonwoven fabrics?

Pet nonwoven fabrics benefit from high melting temperatures, excellent chemical resistance, and durability, making them ideal for applications that require longevity and performance in harsh conditions. They are also known for their hypoallergenic nature, breathability, and ease of cleaning, which reduces matting and shedding.What are common uses of pet nonwoven fabrics?

Common uses include pet bedding, blankets, clothing, hygiene products, and cleaning wipes. Nonwoven fabrics made from recycled PET are particularly suitable for managing odor and controlling shedding, offering a sustainable and easy-to-clean option for pet care products.How are pet nonwoven fabrics produced?

The production involves melting polyester resin, extruding it into filaments, spinning them, and then depositing them randomly on a conveyor belt to form a web. Bonding techniques like thermal, ultrasonic, or chemical methods are used to increase strength and integrity, ensuring the final product is durable and suitable for use in pet care products.What makes pet nonwoven fabrics ideal for pet bedding?

Pet nonwoven fabrics are ideal for pet bedding due to their durability, hypoallergenic properties, and ease of maintenance. They reduce matting, shedding, and offer simple cleaning routines, making them a comfortable and practical choice for both pets and owners.What are the sustainability considerations in the production of pet nonwoven fabrics?

Sustainability is achieved through the use of biodegradable PET derived from recycled plastic bottles, plant-based plastics, and closed-loop recycling systems. Bio-based adhesives and binders, as well as state-of-the-art equipment powered by renewable energy sources, further reduce environmental impact and ensure eco-friendly production practices.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co