Working Principle of Non-Woven Materials in Packaging

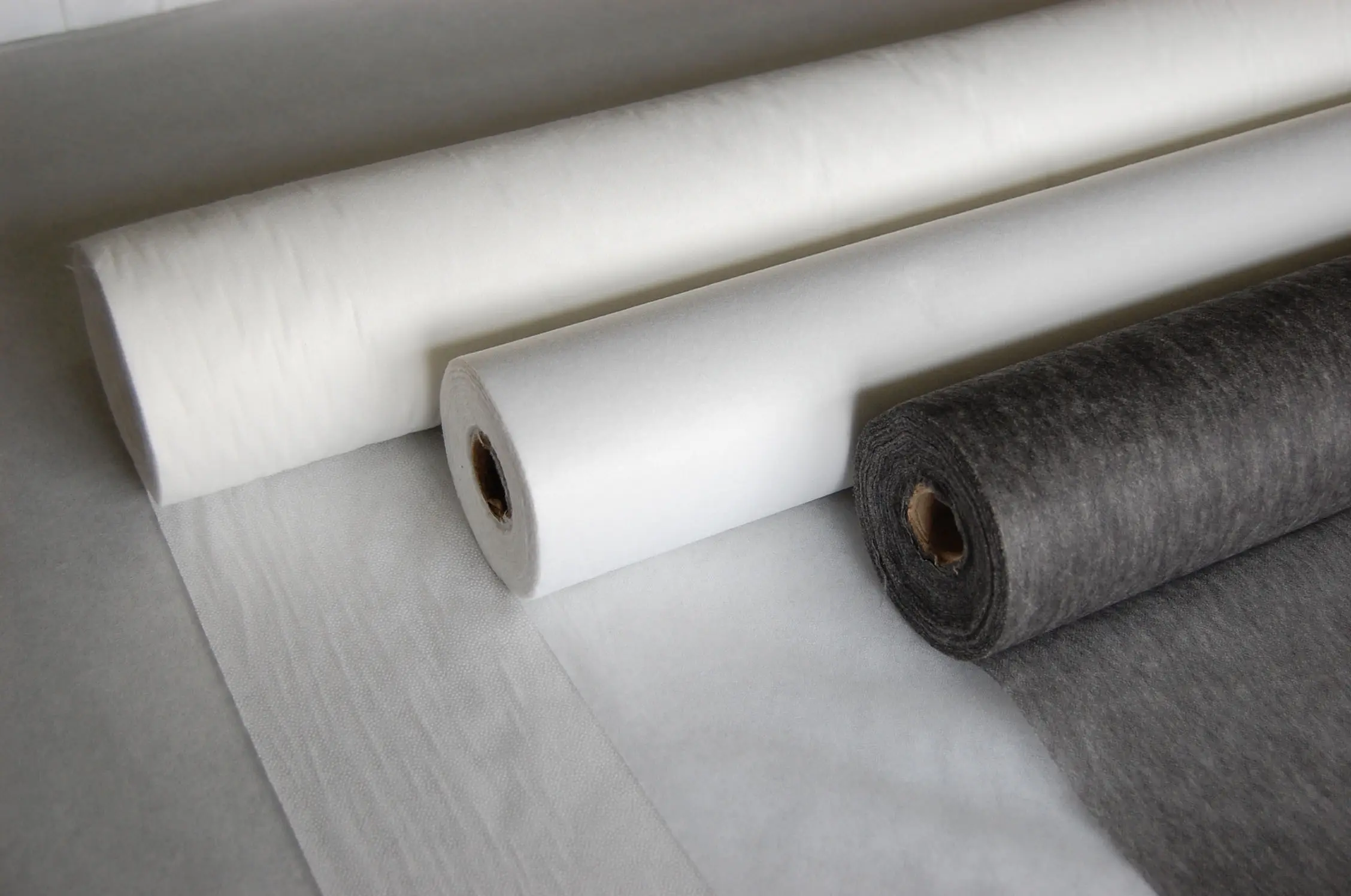

Non-woven materials have emerged as a key player in modern packaging industries, offering a versatile and sustainable alternative to traditional woven fabrics. These materials, often referred to as non-filters or non-impregnated fabrics, have gained prominence due to their unique properties and growing demand for eco-friendly solutions. Unlike woven materials, non-woven fabrics are made from non-continuous fibers that are randomly laid down without the need for a weaving process. This distinctive method of construction imparts them with exceptional flexibility, durability, and a lightweight structure, making them ideal for a wide range of applications.

Historically, non-woven materials were first introduced in the early 20th century, primarily for use in medical applications. Over the past few decades, they have evolved significantly, finding widespread use in various industries, including packaging. The growing awareness of environmental concerns and the push towards sustainable practices has further accelerated their adoption. For instance, companies like Procter & Gamble and Kimberly-Clark have been using non-woven materials for their absorbent products, showcasing their potential in both consumer and industrial sectors.

What Are Non-Woven Materials and How Are They Made?

Non-woven materials are created from a variety of raw materials, including polyester, polypropylene, and cotton. The manufacturing process involves several techniques, each yielding fabrics with distinct characteristics:

1. Spunbonding: This method involves the spinning of fibers into melt-forming jets, which are then extruded onto a moving conveyor belt and laid down to form a non-woven fabric. Spunbonded materials are known for their strength and consistency.

2. Meltblowing: Fibers are melted into fine filaments and laid down onto a wire frame or conveyor belt to form a continuous fabric. Meltblown materials are highly breathable and are often used in medical applications due to their excellent filtration properties.

3. Needle Punching: Fibers are compressed and punched through a mesh of needles to create a permeable fabric. Needle-punched materials are often used in protective clothing and automotive applications due to their durability and breathability.

Each of these techniques results in non-woven fabrics with varying textures and thicknesses, tailored to specific applications. For example, spunbonded materials are ideal for durable packaging, while meltblown fabrics are suitable for disposable gloves due to their high permeability.

Properties and Benefits of Non-Woven Fabrics

Non-woven materials are renowned for their exceptional properties, making them a cost-effective and efficient choice for packaging. Their flexibility allows them to conform to various shapes, which is particularly useful in applications where custom forms are required. Breathability is another key property, enhancing air circulation and reducing product spoilage. This is crucial in the food industry, where maintaining freshness is paramount.

Water resistance and thermal insulation are also important properties that contribute to the longevity and performance of non-woven materials. For instance, non-woven polypropylene is commonly used in disposable medical gowns and surgical masks due to its water-repellent qualities and ability to maintain a sterile environment. In the food packaging industry, non-woven materials can be utilized to create protective barriers that prevent moisture and contaminants from affecting the packaged goods.

Applications of Non-Woven Materials in Packaging

Non-woven materials find extensive use across various industries, including food, medical, and electronics. In the food industry, they are employed for food packaging to ensure freshness and prevent contamination. For example, non-woven materials can be used to make reusable shopping bags, which are durable and eco-friendly alternatives to single-use plastic bags. In the medical sector, non-woven materials are used for surgical gloves and dressings, providing protection and maintaining hygiene.

The electronics industry benefits from non-woven materials in creating protective packaging for sensitive components. These materials are excellent at absorbing shocks and vibrations, safeguarding electronic devices during shipping and handling. For instance, non-woven materials can be used to create bubble wrap alternatives that provide superior cushioning and protection.

Comparison of Non-Woven vs Woven Materials for Packaging

Non-woven materials offer distinct advantages over traditional woven fabrics. They are often more flexible, biodegradable, and recyclable, aligning with global sustainability goals. Woven materials, while durable, are less flexible and may not withstand the same environmental conditions as non-woven ones. Non-woven materials also reduce waste by minimizing material loss during production, making them a cost-effective and efficient choice.

Environmental Benefits and Role in Sustainable Practices

The environmental impact of non-woven materials is significant in promoting sustainability. Their biodegradability and recyclability minimize landfill waste and reduce the environmental footprint of packaging solutions. For example, non-woven materials used in disposable medical gowns can be disposed of in a more environmentally friendly manner compared to traditional plastic alternatives. Case studies have shown that the use of non-woven materials in food packaging can lead to a substantial reduction in waste, aligning with industry-wide efforts to reduce environmental impact.

Challenges and Future Implications

Despite their advantages, non-woven materials face challenges such as ensuring safety, managing supply chain complexities, and addressing technical limitations. However, advancements in material science and technology promise to overcome these hurdles. For instance, new biodegradable materials are being developed to further enhance the sustainability of non-woven fabrics. Future applications may include the integration of smart materials that can monitor environmental conditions, ensuring optimal product protection.

Conclusion

Non-woven materials represent a vital advancement in packaging, offering a sustainable and efficient solution that meets the needs of various industries. As technology continues to evolve, their role in reducing waste and promoting sustainability will only grow. By embracing non-woven materials, companies can not only enhance the performance of their packaging solutions but also contribute positively to environmental conservation. The future of non-woven materials is bright, with ongoing research and development paving the way for even greater innovation and applicability.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co