What is Non Woven Interlining? How to Choose the Right One

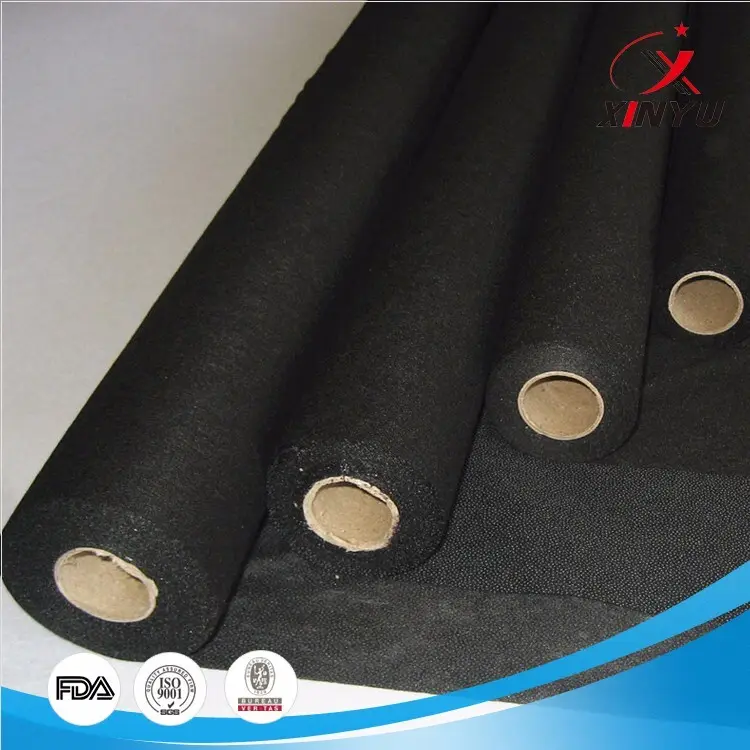

Non-woven interlinings are essential components in garment construction, offering unique properties that significantly enhance the overall performance of clothing. These interlinings are created through the bonding of fibers using thermal, needle punching, or chemical methods, resulting in lightweight, breathable, and uniform materials. They provide excellent insulation while maintaining flexibility and shape retention, making them suitable for a wide range of applications. In outerwear, non-woven interlinings offer warmth and flexibility without adding bulk, improving wearing comfort in jackets and snow pants. For casual wear, they enhance the fit and reduce wrinkles in shirts and sweaters, providing a polished finish.

For formal wear, where rigidity and structure are key, non-woven interlinings can be combined with traditional fusible or sew-in interlinings to achieve the necessary formality and precision. Innovations in non-woven technology, such as the use of eco-friendly materials and advanced composites, further enhance their performance and sustainability. Case studies from various industries demonstrate how these materials can be effectively integrated into garment design, highlighting their versatility and adaptability.

Understanding Non-Woven Interlinings: Types and Applications

Non-woven interlinings come in different types, each with specific applications and benefits:

- Fusible Interlinings (Heat-activated): Ideal for quick and easy projects, such as casual wear. These interlinings are bonded to the garment using heat, providing a seamless and secure fit.

- Sew-in Interlinings (Sewn in by machine or hand): Preferred in high-end, custom tailoring where precise fit and control are crucial. This method offers better durability and overall structural support, making it a favorite in professional wardrobe construction.

- Peel-and-Stick Interlinings (No sewing required): Convenient for quick alterations and DIY projects. These interlinings are easily peeled from their packaging, placed, and smoothed onto the garment, offering a time-saving option for those with limited sewing skills.

- Moisture-Wicking Interlinings (Moisture management capabilities): Essential for warm-weather garments, providing comfort by keeping the wearer dry and reducing heat buildup. These interlinings excel in sports and occupational wear, where maintaining a comfortable body temperature is important.

- Eco-Friendly Interlinings (Sustainable materials): Made from materials like recycled polyester and organic cotton, these interlinings not only meet environmental standards but also perform well in terms of moisture management, breathability, and durability. Choosing these interlinings supports sustainable practices and reduces the environmental impact of garment production.

Non-Woven Interlining Process and Benefits

Non-woven interlinings are produced through various processes, each offering distinct benefits:

- Thermal Bonding: This process involves applying heat and pressure to fuse fibers together, resulting in a strong, flexible, and uniform interlining. It enhances the structure of garments without adding bulk.

- Needle Punching: Using needles to interlock loose fibers or through-coated fibrous layers with a substrate, this method adds tensile strength and improves dimensional stability, making it ideal for heavier fabrics.

- Adhesive Lamination: This technique bonds two or more layers of material together using a synthetic adhesive, providing a sleek, seamless finish that is both strong and flexible. It is ideal for reducing bulk and achieving precise fit.

- Polymer Coating: By applying a thin layer of polymer to the interlining, this method increases durability and water resistance, ensuring the interlining maintains its shape and integrity over time.

- Eco-Friendly Production: Many manufacturers use sustainable materials and processes to reduce the environmental impact, such as recycling and biodegradable adhesives, making non-woven interlinings a greener choice.

Choose Non-Woven Interlining Based on Fabric & Design

When choosing non-woven interlining, consider the fabric and design meticulously. For delicate textiles like light silks, a sheer and lightweight interlining is crucial to complement their texture without overwhelming it. Heavier fabrics, such as wool or cotton blends, require a more substantial interlining to maintain shape and provide necessary support. Properly chosen non-woven interlinings ensure that the interlining does not alter the intended drapery and silhouette of the garment, enhancing its natural characteristics and ensuring a flattering fit.

Effect of Non-Woven Interlining on Garment Fit and Comfort

Non-woven interlinings play a crucial role in determining the fit and comfort of garments. These materials provide essential structure to garments, with firmer interlinings maintaining sharp lines and a crisp appearance in structured pieces like suits. Softer interlinings are vital for garments requiring a fluid drape, such as dresses, as they allow the fabric to flow naturally without compromising comfort.

Moreover, the interlining's moisture management properties are crucial, especially for activewear. Breathability and sweat-wicking capabilities ensure comfort during physical activity. By carefully selecting interlinings based on fabric type and garment design, manufacturers can optimize the fit and overall wearing experience, ensuring that garments meet high expectations.

Sustainable Non-Woven Interlining and Environment

Sustainable non-woven interlinings offer a promising alternative in the fashion industry, reducing waste and minimizing environmental impact. Made from fibers bonded through chemical, thermal, or mechanical processes, these interlinings are increasingly adopted for their versatility and eco-friendliness. Certifications like OEKO-TEX and GOTS, combined with transparent supply chains and circular economy principles, ensure sustainable sourcing and production. Blockchain and IoT technologies further enhance traceability and transparency, providing consumers with verifiable information about the production journey.

By integrating these technologies and adhering to strict sustainability standards, the fashion industry can significantly reduce its environmental footprint while maintaining product quality.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co