Optimal Non-Woven Interlining for Washing Durability

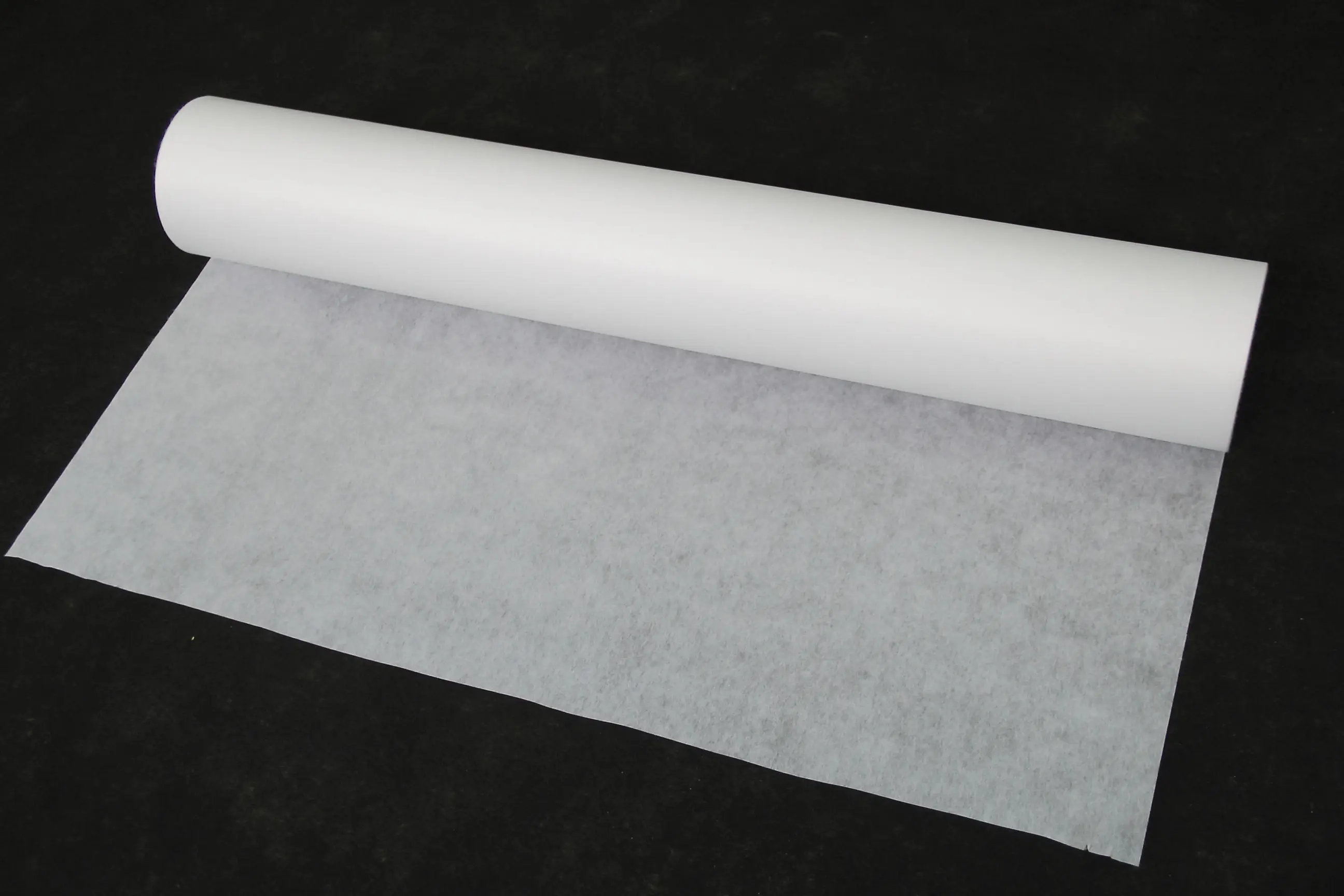

Non-woven fabric interlining is a synthetic material made by layering fibers and blowing them into a mesh using hot air. It is widely used in the fashion industry for its lightweight, flexible, and moisture-wicking properties. Unlike knitted or woven fabrics, non-woven interlinings are not stretched, which makes them ideal for garments that require a natural fit. They are commonly used in items like dresses, skirts, and accessories due to their absorbency and softness.

The application of non-woven interlining has expanded beyond traditional garments to include home furnishings, reinforcing its versatility. It is used in furniture covers, industrial applications, and even medical equipment due to its durability and resistance to chemicals. However, in the context of fashion, the focus is on how non-woven interlining affects the washing durability of garments.

The quality of the non-woven interlining significantly impacts the overall performance of a garment. For instance, a garment with high-quality non-woven interlining may retain its shape and finish even after multiple washes, whereas a lower-quality interlining may degrade prematurely. Therefore, understanding the factors that influence washing durability is essential for manufacturers aiming to produce sustainable and long-lasting garments.

Factors Affecting the Durability of Non-Woven Interlining

The durability of non-woven interlining is influenced by several factors, including material properties, manufacturing processes, and design solutions. Material properties such as tensile strength, absorbency, and chemical resistance play a crucial role in determining how well an interlining holds up during washing. A fabric with high tensile strength, for example, is less likely to tear or stretch excessively during repeated washing cycles.

Manufacturing processes also have a significant impact on durability. The density of the interlining, the type of fibers used, and the presence of fillers or reinforcements are critical factors. Fabrics with higher densities are generally more durable, as they hold together more tightly. The use of flame retardants and anti-acterial agents also enhances the durability of non-woven interlining by making it resistant to stains and odors.

Design solutions, such as reinforced edges and special coatings, can further improve the washing durability of non-woven interlining. Reinforced edges prevent rips and tears, while special coatings can protect the fabric from fading and shrinking. Additionally, the placement of seams and hems is crucial in maintaining the integrity of the garment during washing.

Understanding these factors is essential for manufacturers who aim to produce garments with optimal washing durability. By optimizing the material properties, manufacturing processes, and design solutions, manufacturers can enhance the overall performance of non-woven interlining.

Techniques to Enhance Washing Durability

Enhancing the washing durability of non-woven interlining requires a combination of material treatment, fabric selection, and design strategies. One of the most effective techniques is the use of chemical treatments. For instance, washing with enzymes or bleach can help break down tough stains and improve the absorbency of the fabric. These treatments are particularly useful for garments that require easy washing and maintaining their appearance.

Another technique is the use of mechanical methods to enhance the tensile strength of the fabric. Knitting or weaving the interlining into a denser structure can significantly improve its durability. This process involves layering the fabric and stitching it together, which increases the strength and flexibility of the interlining.

Blending materials is another effective strategy for enhancing washing durability. Adding flexible polymers or other materials to the interlining can improve its resistance to stretching and tearing. This approach is particularly useful for garments that require a natural fit and long-lasting wearability.

In addition to these techniques, the design of the garment plays a crucial role in maintaining washing durability. For example, placing seams and hems in areas that are less likely to be washed can help preserve the integrity of the garment. Similarly, using reinforced stitching in high-stress areas can enhance the durability of the interlining.

By combining these techniques, manufacturers can produce garments with optimal washing durability, ensuring that customers receive high-quality products that meet their expectations.

Challenges and Solutions in Using Non-Woven Interlining

Despite the numerous benefits of non-woven interlining, there are several challenges that manufacturers and retailers face when it comes to achieving washing durability. One of the primary challenges is meeting customer expectations. Customers often have high standards for garment quality, and any issues with washability can lead to dissatisfaction.

Another challenge is the washing durability of the interlining itself. Non-woven fabrics are generally more durable than traditional knitted or woven fabrics, but they are not immune to wear and tear. Factors such as the number of washes, the type of detergent used, and the washing machine settings can significantly impact the lifespan of the interlining.

Retailers also face challenges in balancing customer expectations with production costs. While improving the washing durability of non-woven interlining is essential, it can also increase the cost of production. Retailers must find a way to offer high-quality garments without compromising on affordability.

Case studies of successful solutions highlight the importance of investing in high-quality non-woven interlining. For example, brands that prioritize the use of reinforced interlining and special coatings have been able to produce garments that maintain their appearance and durability even after multiple washes. These retailers have also been able to meet customer expectations by offering a wide range of designs and sizes.

By addressing these challenges and implementing best practices, manufacturers and retailers can produce garments with optimal washing durability, ensuring customer satisfaction and long-term success.

Testing Methods for Wash Durability of Non-Woven Interlining

Testing the wash durability of non-woven interlining is a critical step in ensuring that garments meet customer expectations. Common testing methods include washing cycles, fade tests, and machine-washability tests. Washing cycles involve subjecting the fabric to repeated washing and drying to simulate real-world use. Fade tests assess the fabric's resistance to fading, while machine-washability tests evaluate how well the fabric retains its shape and finish when washed in a washing machine.

These testing methods provide valuable insights into the performance of non-woven interlining under different conditions. For example, testing the fabric's resistance to water and chemicals can help manufacturers select the right materials for specific applications. Similarly, testing the fabric's ability to withstand extreme temperatures and entrenched stains can help improve the overall durability of the interlining.

By implementing rigorous testing methods, manufacturers can ensure that their products meet high standards of quality and durability. This not only enhances customer satisfaction but also builds brand reputation and loyalty.

Customer Feedback and Retailer Response

Customer feedback on the washability and durability of non-woven interlining is essential for manufacturers and retailers to improve their products. Customers often care deeply about the ease of washing and the long-lasting wearability of their garments. Negative feedback on these aspects can lead to dissatisfaction and a loss of customer trust.

Retailers must respond to customer feedback in a way that balances product quality with affordability. For example, introducing new designs or patterns that meet specific customer preferences can help attract a wider range of customers. Additionally, retailers can offer guarantees or warranties on their products to address concerns about washing durability.

Analyzing customer feedback and retailer responses can provide valuable insights into the evolving needs of the market. For instance, customers may increasingly demand garments that are not only durable but also easy to wash. Retailers must adapt to these changing demands by investing in research and development to create innovative solutions.

In conclusion, non-woven interlining plays a crucial role in enhancing the washing durability and overall performance of garments. By understanding the factors that influence washing durability, implementing effective techniques, and addressing customer feedback, manufacturers and retailers can produce high-quality garments that meet the expectations of their customers.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co