Eco-Friendly Options for Non-Woven Fabric Interlining

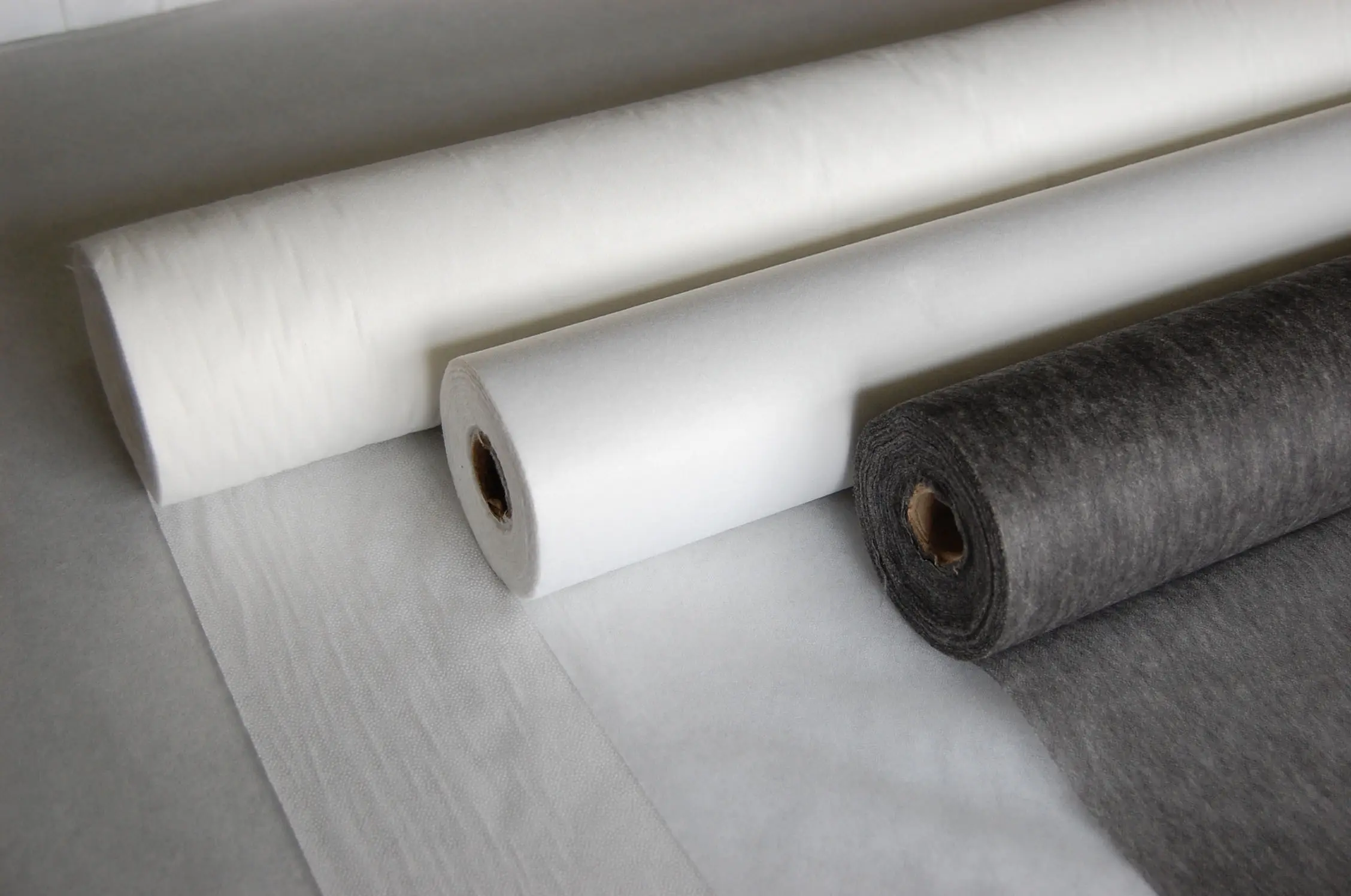

Non-woven fabric interlining offers versatile and sustainable alternatives to traditional woven interlinings, making it a popular choice in garment production. Created through methods like batting, thermal bonding, or needle punching, these interlinings provide lightweight and flexible materials suitable for various designs. Non-woven fabrics can be made from natural fibers such as cotton and synthetic materials like polyester, often incorporating recycled content to reduce waste. The production process generally consumes less water and energy, contributing to a lower environmental footprint compared to traditional interlinings. Additionally, non-woven interlinings can be more easily recycled at the end of a garments lifecycle, further enhancing their eco-friendliness. These materials not only support sustainable design goals but also improve comfort and performance in finished garments, making them a valuable choice for designers and manufacturers committed to reducing the environmental impact of their production processes.

Environmental Impact of Non-Woven Fabric Interlining

The environmental impact of non-woven fabric interlining is critical in the pursuit of sustainability. These interlinings provide essential structural support and shape retention in clothing but face scrutiny due to their production methods and material composition. Biodegradability and reduced chemical usage are key areas of focus. Sustainable alternatives like plant-based fibers such as bamboo and hemp, and recycled materials, offer promising solutions. These materials not only reduce the interlinings environmental footprint but also contribute to lower carbon emissions and reduced chemical pollutants. The production process also plays a significant role, with initiatives such as energy efficiency through renewable sources and integrated waste management systems further enhancing sustainability. By adopting these practices, manufacturers can significantly reduce the overall environmental impact of non-woven fabric interlining, making fashion more sustainable and environmentally friendly.

Innovations in Eco-Friendly Non-Wovens

Innovations in eco-friendly non-wovens are rapidly advancing, driven by technological breakthroughs and environmental necessity. Biodegradable materials such as PLA (polylactic acid) and cellulose-based fabrics show significant promise, offering comparable performance to traditional non-wovens while reducing environmental impact. Biorefineries and 3D printing enhance the cost-effectiveness and scalability of these materials through optimized production processes and precise material usage. Advancements in enzyme technologies improve biodegradation rates, making these materials more versatile and sustainable. Regulatory support through stringent certification standards and government incentives ensures market transparency and encourages broader adoption. Collaboration between textile manufacturers, chemical companies, and research institutions accelerates the development and implementation of biodegradable non-wovens, making eco-friendly options the norm in the non-woven sector.

Cost Considerations and Market Analysis

Cost considerations for eco-friendly non-woven fabric interlinings reflect higher initial costs due to sustainable materials and production processes, which are gradually decreasing with increased demand. Consumers are increasingly willing to pay more for sustainable products, particularly those with recognized certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX. Retailers and manufacturers can effectively communicate these benefits through transparent labeling, educational content, and marketing campaigns that highlight lifecycle advantages and cost savings. Strategic partnerships with environmental organizations and sustainability-focused influencers enhance market reach and product acceptance, making eco-friendly interlinings a viable and attractive option in the competitive fabric market.

Applications and Effectiveness of Waste Management

Effective waste management in the non-woven fabric interlining industry involves a multifaceted approach that leverages innovations in recycling and upcycling, with collaboration among stakeholders. Circular economy models reuse and recycle used non-woven materials, significantly reducing environmental impact. Biodegradable and compostable materials offer promising directions for sustainable practices, minimizing waste and enhancing product sustainability. Collaboration between manufacturers, recycling facilities, and consumers is crucial for driving greater adoption of eco-friendly practices. Clear recycling guidelines from manufacturers, sourcing from certified recycled materials, and enhancing communication on material types and quality by recycling facilities are key. Consumer education through sustainability commitments and accessible recycling information encourages proper disposal and recycling. Innovative recycling technologies such as advanced sorting methods, chemical recycling, and mechanical recycling enhance the recycling and upcycling processes. Policy and regulatory frameworks promote adoption through incentives and subsidies, with industry associations setting uniform standards. Public-private partnerships and extended producer responsibility programs facilitate technology transfer and scaling.

Regulatory Landscape and Sustainability Practices

The regulatory landscape plays a crucial role in shaping sustainability practices within the non-woven fabric industry. Regulations such as REACH in Europe and GHS globally encourage safer materials and more transparent supply chains. companies are adopting eco-friendly alternatives like biodegradable and plant-based fibers, along with advanced recycling technologies. Higher initial costs and technological complexity pose challenges, but collaborative efforts and standardization can foster broader adoption. Industry partnerships, policy incentives, and transparent supply chain practices enhance sustainability. Blockchain technology and other tools enhance supply chain transparency, while green spaces and community involvement ensure equitable distribution of sustainability benefits, fostering a more inclusive and environmentally conscious industry.

Conclusion and Future Trends

Significant advancements in biodegradable materials, recycling technologies, and energy-efficient production processes have been made to achieve eco-friendly non-woven fabric interlinings. Emerging technologies like PLA and advanced recycling methods are paving the way for more sustainable practices. Supply chain transparency through educational programs and consumer awareness campaigns play crucial roles in engaging consumers and promoting sustainable choices. Digital marketing strategies, including virtual reality and gamification, effectively reach broader audiences and reinforce the importance of eco-friendly materials. As these trends continue to evolve, integrating green spaces and community involvement in sustainability initiatives will be essential for ensuring equitable benefits and fostering a more inclusive and environmentally conscious industry.

FAQs Related to Non-Woven Fabric Interlinings and Their Eco-Friendly Alternatives

What are non-woven fabric interlinings, and how are they produced?

Non-woven fabric interlinings are lightweight and flexible materials used for improved structure and shape retention in clothing. They are produced through methods such as batting, thermal bonding, or needle punching, using natural fibers like cotton and synthetic materials like polyester, often incorporating recycled content to reduce waste.What are the environmental impacts of non-woven fabric interlining?

The production of non-woven fabric interlining generally consumes less water and energy, offering a lower environmental footprint compared to traditional interlinings. Additionally, these materials can be more easily recycled at the end of a garments lifecycle, further enhancing their eco-friendliness.What are some eco-friendly alternatives to traditional non-woven fabric interlinings?

Eco-friendly alternatives include biodegradable materials like PLA (polylactic acid) and cellulose-based fabrics, which offer comparable performance to traditional interlinings but with a reduced environmental impact. These materials are often made from plant-based fibers such as bamboo and hemp, and recycled materials.What are the cost considerations for using eco-friendly non-woven fabric interlinings?

Eco-friendly non-woven fabric interlinings have higher initial costs due to sustainable materials and production processes. However, these costs are gradually decreasing as demand increases. Consumers are willing to pay more for sustainable products with recognized certifications such as GOTS (Global Organic Textile Standard) or OEKO-TEX, and strategic partnerships with environmental organizations can enhance market acceptance.How are waste management and recycling handled in the non-woven fabric interlining industry?

Effective waste management involves recycling and upcycling used non-woven materials, promoting circular economy models. Biodegradable and compostable materials are promising for sustainable practices, minimizing waste and enhancing material sustainability. Collaboration between manufacturers, recycling facilities, and consumers is crucial for driving greater adoption of eco-friendly practices through clear guidelines and policy frameworks that promote incentives and subsidies.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co