What is Non Woven Adhesive Used For?

Imagine a world where sticky materials never fall off and can be used in countless applications. Non-woven adhesives are like magic in this respect, providing strong, durable bonds in a wide range of products and environments. From the moment you peel off a bandage to the moment you walk into a building with energy-efficient insulation, non-woven adhesives are quietly at work, enhancing our daily lives.

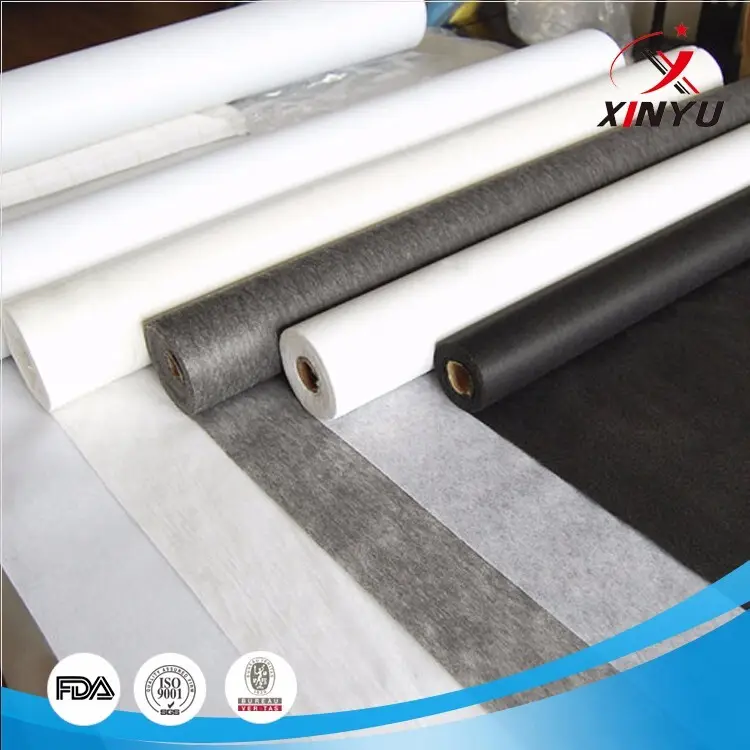

Properties of Non-Woven Adhesives

Non-woven adhesives are distinguished by their unique combination of properties. They are highly flexible, allowing them to conform to various surfaces without breaking or cracking. Durability is another key trait, ensuring that the adhesive remains strong over time, even in challenging conditions. Additionally, they are easy to apply, making them versatile for both industrial and consumer use.

- Flexibility: Non-woven adhesives can adhere to irregular surfaces without losing their bond.

- Durability: They maintain their strength under various conditions, including heat, moisture, and UV exposure.

- Ease of Application: Non-woven adhesives can be easily applied using standard tools, reducing the need for specialized equipment.

Applications Across Industries

Non-woven adhesives find their place in a diverse portfolio of industries, each benefiting from their unique properties.

Textile Industry

In the textile industry, non-woven adhesives are used to bond fabrics together, creating durable and weather-resistant clothing and home products. For instance, in outdoor gear and personal protective equipment, these adhesives ensure that materials stay intact and functional.

Healthcare Industry

In healthcare, non-woven adhesives are a critical component in bandages and medical devices. They provide strong, flexible bonds that are crucial for keeping bandages in place and ensuring that medical devices adhere securely to skin. Non-woven adhesives are also used in disposable hygiene products, such as diapers and surgical gowns, where durability and safety are paramount.

Construction Industry

In construction, non-woven adhesives are used in insulation and roofing materials. For example, they help create energy-efficient roofing systems that maintain seals and improve the overall sustainability of buildings. Non-woven adhesives are also used in wall and ceiling panels, ensuring a secure and stable installation.

Environmental Protection

In environmental applications, non-woven adhesives are used for lining and protecting surfaces in green spaces and industrial sites. They help prevent water and soil contamination, contributing to a healthier environment.

Technical Aspects of Production and Comparison

Non-woven adhesives are produced using a variety of formulations, often involving non-woven fabrics and binders. The production process typically involves mixing and applying the adhesive to form a flexible material that can be used in various applications. Compared to traditional adhesives, non-woven adhesives often offer better performance in terms of strength and durability, while also being more cost-effective and environmentally friendly.

- Formulation: Non-woven adhesives are designed to meet specific performance requirements, such as flexibility and adhesion strength.

- Application Methods: They can be applied in various ways, including spraying, coating, or spreading, depending on the application needs.

Sustainability and Environmental Impact

The environmental benefits of non-woven adhesives are significant. They are often biodegradable, which makes them a sustainable choice for industries concerned with environmental responsibility. This biodegradability helps reduce waste and lowers the carbon footprint associated with their production and use. Non-woven adhesives are also used in sustainable practices across industries, helping to minimize environmental impact while maintaining high standards of performance.

Broader Applications: Medical, Construction, and Beyond

Non-woven adhesives have applications beyond the industries mentioned. In the medical field, they are used to create advanced medical devices and prosthetics, ensuring durable and reliable performance. In construction, they are used for insulation and roofing materials, contributing to energy efficiency and long-lasting structures.

- Medical Devices: Non-woven adhesives enable the creation of secure and long-lasting medical devices, from surgical masks to smartwear.

- Insulation: They improve the thermal performance of buildings, reducing energy consumption and environmental impact.

Conclusion

Non-woven adhesives are more than just versatile and flexible adhesives; they are a critical component of modern industries, offering unique properties and benefits that make them indispensable in many applications. From textiles and healthcare to environmental protection and construction, non-woven adhesives play a vital role in enhancing the durability and performance of various products and systems. As technology continues to advance, non-woven adhesives are likely to play an even more significant role in shaping the future of production and innovation.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co