What Are Garment Interlining Specs?

Interlining is a crucial component that significantly impacts the overall quality of a garment. It is typically applied to the inside of fabrics and can be made from various materials, each offering unique benefits. For instance, interlining can enhance the breathability of a garment, making it more comfortable for the wearer. It can also improve durability by protecting the inner lining from wear and tear. Furthermore, interlining can influence the fit and shape of the garment, allowing it to be tailored to specific needs. Without interlining, garments may lack the desired comfort and performance.

How Interlining Affects the Fit and Shape of Garments

The effect of interlining on the fit and shape of garments is profound. Different types of interlining influence how a garment conforms to the body, offering varying levels of stretch and drape. For example, bonded interlining, which is sewn directly to the fabric, provides more stretch and durability. This type is commonly used in running wear where breathability and durability are paramount. On the other hand, unbonded layer interlining, which is sewn separately and then stitched into place, is softer and offers less stretch, often used in casual wear for its comfortable feel. Additionally, metallic interlining, used in formal wear, adds a reflective finish and enhances the garment's appearance. Bi-fold interlining is employed in outerwear for insulation and water resistance. Each type of interlining is chosen based on the fabric's properties, such as stretch percentage, weight, and moisture-wicking ability.

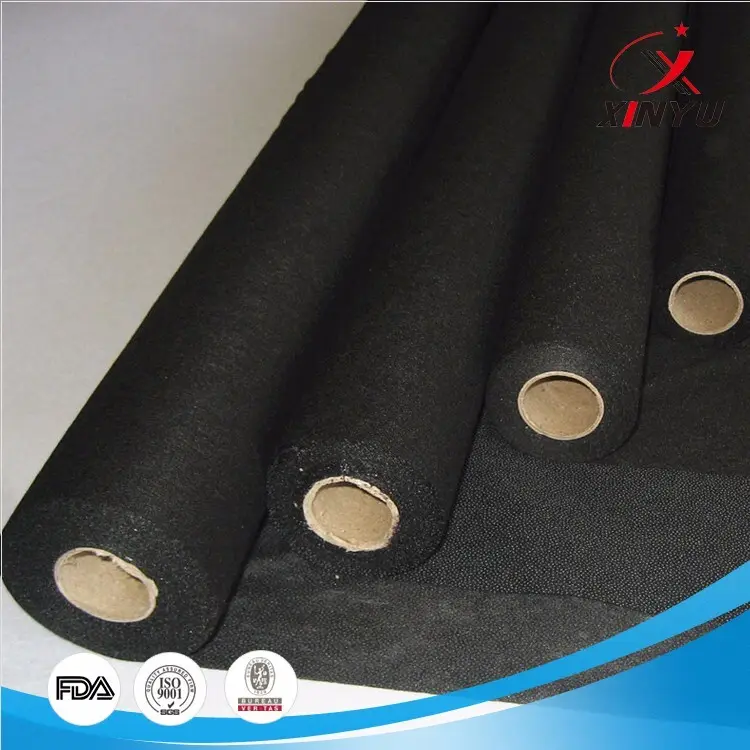

Different Types of Interlining and Their Applications

There are various types of interlining, each serving specific purposes in different garment categories. Bonded interlining is typically used in sports apparel for its durability and ability to enhance breathability. Unbonded layer interlining is often found in everyday wear for its softness and comfortable feel. Metallic interlining is used in formal wear to add a reflective finish and improve the garment's appearance. Bi-fold interlining is employed in outerwear for insulation and water resistance. Each type of interlining is carefully selected to meet the specific needs of the garment, ensuring optimal performance and comfort.

Considering Design Specifications for Optimal Interlining

Designers play a crucial role in selecting the appropriate interlining for their garments. They must consider the fabric's properties, such as stretch percentage, weight, and moisture-wicking ability, to achieve the desired fit and aesthetic. For instance, a designer aiming for a tailored look might opt for a stretch interlining, while someone seeking a casual, comfortable feel might choose a softer interlining. Understanding these properties allows designers to create garments that meet specific design goals, balancing functionality and style effectively. By carefully selecting interlining, designers can improve the overall quality and user experience of the final product.

Industry Standards and Technical Specifications for Garment Interlining

Industry standards and technical specifications for interlining are essential for ensuring quality and consistency across garments. These standards, such as those outlined in ISO 19205, dictate criteria for materials, including fire resistance, breathability, and durability. Manufacturers must adhere to these standards to meet safety and quality requirements. Compliance with these standards not only ensures that garments meet consumer expectations but also contributes to the industry's overall quality and reputation. Adhering to these guidelines helps maintain high standards of performance and safety in garment manufacturing.

Environmental Implications and Eco-Friendly Alternatives for Interlining

The environmental impact of interlining materials is a growing concern. Many traditional interlinings, such as certain synthetic fabrics, can contribute to pollution. However, there are eco-friendly alternatives available, such as biodegradable or recycled fabrics. These alternatives not only reduce environmental impact but also align with growing consumer demand for sustainable products. Using eco-friendly interlinings can help reduce the carbon footprint of garments while maintaining quality and performance. By incorporating sustainable practices, manufacturers can produce garments that are both high in quality and environmentally responsible.

Conclusion

In conclusion, interlining is a vital component in the garment manufacturing process, significantly influencing the garment's comfort, durability, and fit. From bonded interlining in sports apparel to bi-fold interlining in outerwear, each type serves specific purposes tailored to the garment's intended use. Designers must carefully consider fabric properties when selecting interlining, ensuring the final product meets design goals and quality standards. As the industry evolves, embracing eco-friendly materials becomes more important, offering a sustainable alternative to traditional interlinings. By understanding and utilizing interlining effectively, manufacturers can produce high-quality garments that meet both consumer needs and environmental standards.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co