How Knitted Fusible Interlining Differs for Various Fabrics

Understanding knitted fusible interlinings is essential for improving the performance of knitted garments. These interlinings, typically made from polyamide or recycled polyester, offer key benefits, including enhanced drape and elasticity while minimizing bulk. They are particularly useful in creating comfortable and shape-retaining garments like sweaters. The choice of interlining density and structure depends on the specific knit fabric, with lighter interlinings suitable for fine knits and denser layers appropriate for heavier fabrics. Breathability and moisture management are crucial, enhancing wearer comfort and the garment's longevity. Precision needle-less bonding techniques maintain the natural drape, reducing stretching and puckering. Sustainable options, such as recycled polyester and Tencel, not only match traditional interlinings in performance but also offer environmental benefits, making them popular in the sustainable fashion movement.

Enhancing Fabric Structure with Knitted Fusible Interlining

Enhancing fabric structure through the use of knitted fusible interlining involves selecting appropriate materials and techniques. The choice of interlining varies based on the knit type and its density and composition. For example, interlinings for knitted tops should provide better shape retention and prevent stretching, whereas those for jackets should enhance structural integrity and offer increased warmth. The interlining must perform well under environmental factors such as washing and regular wear, maintaining its adhesion and performance. Biodegradable and recycled materials are increasingly used to reduce the environmental impact of garment production. Innovations in smart materials and digital tools are facilitating the development of more sustainable and optimized interlinings, making them more accessible to manufacturers and consumers. These advancements empower designers to create garments that are aesthetically pleasing and environmentally responsible.

Suitability of Knitted Fusible Interlining

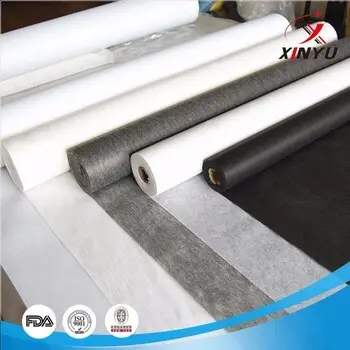

Knitted fusible interlining is versatile and suitable for various fabrics, enhancing stability, drape, and finish. The selection of interlining depends on the weight and knit structure of the fabric. Lighter knits benefit from finer, more flexible interlinings to prevent bulkiness, while heavier fabrics like fleece can handle slightly thicker and more structurally supportive options. Different types of knitted interlinings, such as jersey, rib, and lace, offer varying degrees of drape, stability, and elasticity, making them ideal for specific applications. For example, jersey knits provide a smooth, stretchy interlining suitable for maintaining drape and comfort in stretchy garments. Rib knits offer elasticity and shape retention, while lace knits provide a delicate, breathable option for intricate designs. Proper selection of interlining materials, such as polyester, cotton, or silk, influences the final garment's performance and appearance, with considerations including moisture resistance, breathability, and flame retardancy.

Advantages and Disadvantages of Using Knitted Fusible Interlining

Knitted fusible interlining offers several advantages and some limitations. Improved fit and shape maintenance are key benefits, as it allows the garment to conform perfectly to the body. Enhanced durability and increased comfort are also provided by the additional stability and stretchability without bulkiness. Heating and pressure apply the interlining easily, making it a convenient choice for professionals and hobbyists alike. However, heavier interlinings can sometimes make lighter fabrics appear stiff and less flexible, potentially reducing comfort. Therefore, it is essential to consider the interlining weight and the fabric's inherent characteristics when making choices.

Applications of Knitted Fusible Interlining in Garment Manufacturing

Knitted fusible interlinings significantly enhance the performance and comfort of various garment types. They are particularly effective in preserving the elasticity and shape of cotton, silk, and synthetic fabrics, improving both durability and wearability. By providing a stretchable base, these interlinings ensure that the face fabrics maintain their intended form and absorb movement while retaining breathability. The adhesive backing of knitted fusible interlinings ensures secure placement, which is crucial for maintaining the overall quality and fit of the garment. Moreover, they improve the garment's washability and longevity by reducing wrinkles and maintaining shape after repeated washes. The use of eco-friendly materials like recycled polyamides and biodegradable adhesives further enhances sustainability. Advancements in biodegradable adhesives and knitting techniques are making these interlinings more sustainable and effective, aligning with the fashion industry's growing commitment to ecological responsibility.

Environmental and Sustainable Interlining Considerations

Sustainability and environmental impact should be prioritized when selecting interlinings for various fabrics, particularly knits. Natural fibers such as Tencel and organic cotton are preferred to minimize reliance on synthetic, petroleum-based materials. Certifications like OEKO-TEX and Bluesign ensure that production processes meet strict environmental and health standards. Incorporating recycled content and biodegradable options minimizes the long-term environmental footprint. Collaborative efforts between designers, manufacturers, and interlining suppliers are essential for innovation and sustainability. Life cycle assessments (LCAs) play a vital role in evaluating the environmental impact throughout the product's lifecycle. Local sourcing and efficient logistics, such as the use of electric vehicles and renewable energy sources, further reduce the carbon footprint. Innovative marketing strategies, social media challenges, and interactive community events can educate consumers and encourage the adoption of sustainable practices. Technical considerations, such as the durability and comfort of sustainable interlinings, ensure that these materials meet quality standards and contribute to extending the lifecycle of garments, thereby reducing waste and promoting sustainable fashion.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co