Essential Wrapping Tapes for Manufacturers

Transferred wrapping tapes are an indispensable tool in the manufacturing industry, playing a pivotal role in ensuring product protection, efficient logistics, and seamless distribution. This guide delves into the importance of transferred wrapping tapes, exploring their types, benefits, environmental impact, and best practices for manufacturers.

Introduction to Transferred Wrapping Tapes

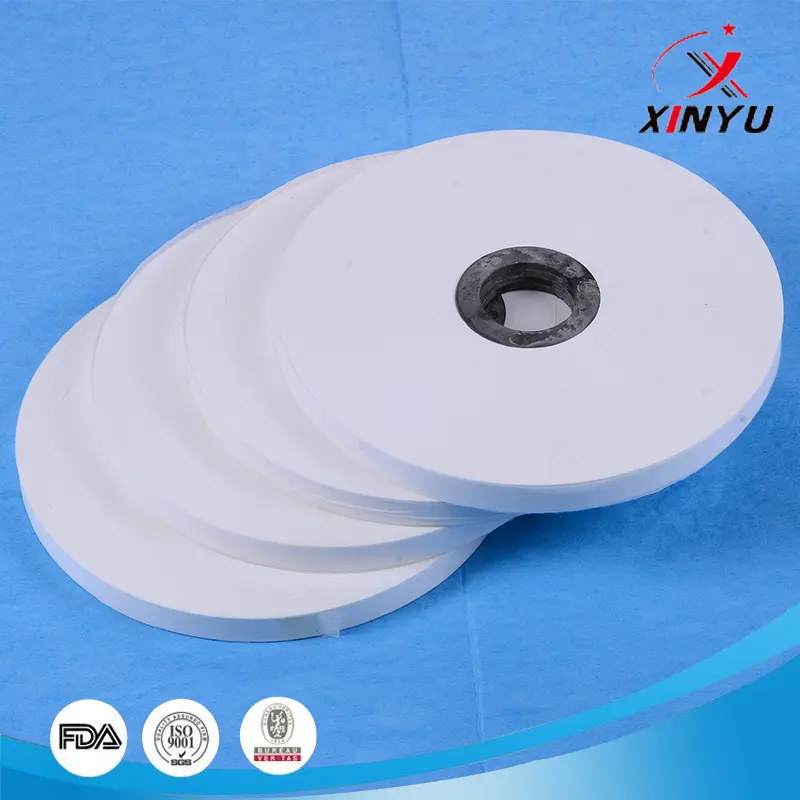

Transferred wrapping tapes are specialized materials designed to wrap and protect products during transportation and storage. These tapes are made from high-quality materials, often featuring strong adhesion, durability, and versatility. They are widely used in manufacturing to ensure that products remain safe, secure, and ready for sale.

In the context of logistics and supply chain management, transferred wrapping tapes are essential for minimizing damage to fragile or perishable goods. By providing a snug fit around products, these tapes help maintain their integrity throughout transit. Additionally, they reduce the risk of damage during handling and storage, ensuring that products arrive in perfect condition.

Transferred wrapping tapes are also critical in the retail sector, where they are used to protect products in display cases and on shelves. Their ability to adhere to various surfaces makes them a popular choice for branding and showcasing products.

Types of Transferred Wrapping Tapes and Their Uses

There are several types of transferred wrapping tapes, each with unique properties and applications. Below is an overview of the most common types:

Plastic Wrapping Tapes: These tapes are made from polyethylene or similar plastics and are known for their flexibility and durability. They are ideal for protecting soft goods, such as fruits, vegetables, and electronics.

Elastic Wrap Tapes: Elastic wrapping tapes are designed to conform to curved surfaces, making them perfect for wrapping cylindrical or rounded items, such as bottles and cans.

Pressure-Sensitive Wrapping Tapes: These tapes feature adhesive properties that allow them to stick to surfaces without leaving residues. They are commonly used in high-volume manufacturing environments where quick and efficient wrapping is essential.

Double-Sided Adhesive Wrapping Tapes: These tapes are ideal for temporary applications, such as packaging materials or temporary displays. They can be adhered to both sides, making them highly versatile.

Printed Transfer Wrapping Tapes: These tapes are designed for branding purposes, featuring printed logos or graphics. They are widely used in the retail and food industries.

Each type of transferred wrapping tape has its unique advantages and is tailored to specific industrial applications.

Benefits of Using Transferred Wrapping Tapes

The use of transferred wrapping tapes offers numerous benefits to manufacturers, including:

Product Protection: Transferred wrapping tapes provide a robust layer of protection for products, safeguarding them against environmental factors such as moisture, temperature fluctuations, and physical damage.

Ease of Application: These tapes are easy to apply, even in tight spaces, making them ideal for wrapping fragile or awkwardly shaped items.

Versatility: Transferred wrapping tapes can be used in a wide range of industries, from food and beverage to electronics and automotive.

Environmental Efficiency: Many transferred wrapping tapes are made from recycled materials, reducing their environmental footprint.

Case studies have shown that manufacturers who adopt transferred wrapping tapes experience significant reductions in waste, damage, and transportation costs.

Environmental Impacts and Sustainable Wrapping Tapes

The environmental impact of transferred wrapping tapes cannot be overlooked. Traditional wrapping tapes often consist of non-recyclable materials, contributing to waste and pollution. However, manufacturers are increasingly adopting sustainable and eco-friendly wrapping tapes.

Sustainable transferred wrapping tapes are made from materials such as recycled plastics, bamboo, and renewable resources. These tapes not only reduce environmental impact but also align with global sustainability goals.

For example, biodegradable wrapping tapes decompose naturally, minimizing the risk of pollution. Recyclable tapes, on the other hand, can be processed into new materials, reducing the overall environmental footprint.

By choosing sustainable transferred wrapping tapes, manufacturers can reduce their carbon footprint while meeting regulatory requirements and consumer expectations.

Cost-Effective Wrapping Tapes

Transferred wrapping tapes offer significant cost savings for manufacturers. While the initial investment in high-quality tapes may seem daunting, the long-term savings are substantial:

Reduced Waste: By protecting products during transit and storage, transferred wrapping tapes minimize the risk of damage and waste, reducing costs associated with repairs and recycling.

Lower Transportation Costs: Products that are properly wrapped are less likely to incur damage during transit, reducing the need for additional protective packaging and lowering shipping costs.

Increased Profit Margins: By reducing waste and optimizing packaging, manufacturers can increase their profit margins and improve their bottom line.

A comparative analysis of transferred wrapping tapes reveals that the cost savings often outweigh the initial investment, making these tapes a financially sound choice for manufacturers.

Best Practices for Using Transferred Wrapping Tapes

To maximize the benefits of transferred wrapping tapes, manufacturers should adhere to the following best practices:

Select the Right Tape for the Task: Choose a transferred wrapping tape that is suitable for the type of product and application. For example, elastic tapes are ideal for curved items, while printed transfer tapes are best for branding purposes.

Adhere to Adhesion Guidelines: Follow the manufacturers instructions for applying the tape to ensure proper adhesion. This will help prevent peeling, lifting, or damage during handling and storage.

Use the Correct Quantity: Overusing transferred wrapping tapes can lead to waste, while underusing them can result in damage. Optimize tape usage based on production volumes and product requirements.

Store Tapes Properly: Keep transferred wrapping tapes in a dry, sealed container to preserve their quality and prevent contamination.

By following these best practices, manufacturers can fully leverage the benefits of transferred wrapping tapes.

Regulatory Requirements and Compliance

Transferred wrapping tapes are subject to various regulatory requirements and industry standards. Manufacturers must ensure that the tapes they use comply with safety, environmental, and quality standards.

Key regulatory considerations include:

Material Safety: Transferred wrapping tapes must be made from materials that are safe for use in manufacturing environments. For example, they should not contain harmful chemicals that could cause toxicity or degradation.

Environmental Compliance: Manufacturers must adhere to environmental regulations regarding waste management and recycling. Sustainable transferred wrapping tapes are often preferred in environmentally conscious markets.

Quality Standards: Transferred wrapping tapes must meet specific quality criteria, such as tensile strength, adhesion, and durability.

By complying with these regulations, manufacturers can avoid penalties and ensure their operations meet industry standards.

Conclusion

Transferred wrapping tapes are an essential tool for manufacturers, offering protection, efficiency, and cost savings. From selecting the right type of tape to adhering to regulatory requirements, manufacturers can maximize the benefits of these tapes.

In conclusion, manufacturers who invest in high-quality transferred wrapping tapes can enhance their operations, reduce costs, and improve product safety. By embracing the latest advancements in transferred wrapping technology, manufacturers can stay competitive in an increasingly demanding market.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co