Comparative Analysis of Thermal Bonding in Nonwovens

Thermal bonding is a manufacturing process that involves the fusion of fibers or fabrics using heat and pressure to create a strong bond. In the context of nonwovens, this process is crucial for producing materials with exceptional strength, flexibility, and durability. Nonwoven materials are made from fibers like polyester, polypropylene, and cotton, which are laid down and treated with an adhesive or coating to form a flexible mat. The primary purpose of thermal bonding is to fuse this mat to a backing material, such as paper, fabric, or foam, to create a finished product.

The process of thermal bonding begins with the laying down of fibers in a controlled environment. These fibers are then coated with a layer of adhesive, which is heated and pressed against a backing material. The heat melts the adhesive, allowing the fibers to adhere to the backing. This method ensures that the final product has a uniform thickness and a consistent texture, making it ideal for various uses.

Thermal bonding is a cornerstone of the nonwoven industry, as it provides a cost-effective and efficient way to produce materials that meet stringent quality standards. Whether its for industrial applications, healthcare, or consumer goods, thermal bonding plays a pivotal role in shaping the final product.

Advantages of Thermal Bonding in Nonwovens

One of the most significant advantages of thermal bonding is its cost-effectiveness. Unlike other bonding methods, thermal bonding requires minimal investment in specialized equipment and chemicals. The process is straightforward, making it accessible to manufacturers with limited resources. Additionally, the materials produced through thermal bonding are highly durability, which reduces the need for replacement and lowers overall production costs.

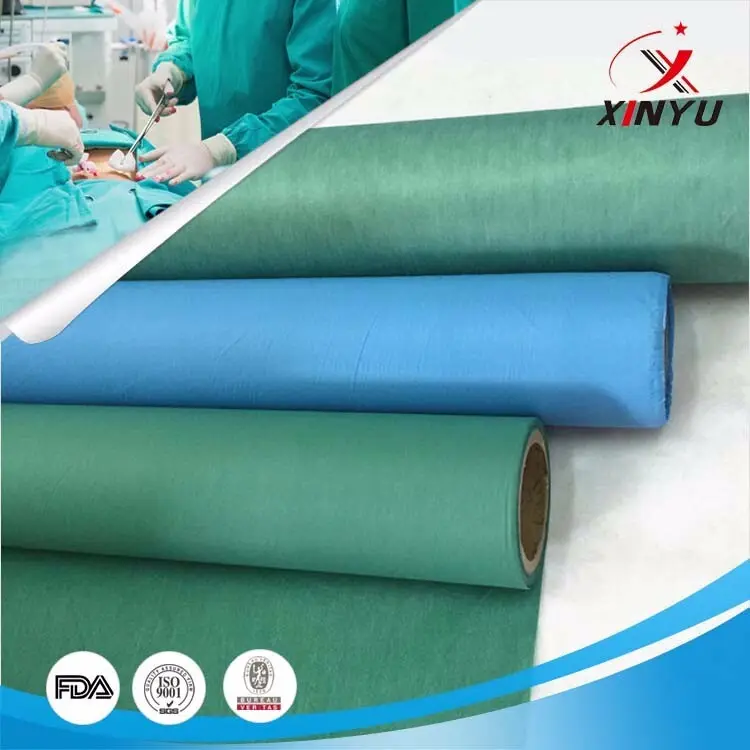

Another benefit of thermal bonding is its versatile nature. The process can be applied to a wide range of materials, including natural fibers and synthetic polymers. This flexibility allows manufacturers to produce nonwoven products tailored to specific industries and applications. For example, medical-grade nonwovens, such as bandages and surgical gloves, are often produced using thermal bonding due to their need for strength and sterility.

Moreover, thermal bonding ensures the creation of products with consistent quality. The controlled heating and pressing process results in uniform thickness and texture, which is essential for the functionality and performance of nonwoven materials. This consistency also simplifies the production process, reducing waste and improving efficiency.

Comparison of Thermal Bonding vs Other Bonding Methods for Nonwovens

While thermal bonding is highly effective, it is not without its limitations. When compared to other bonding methods, such as wet bonding, needlepoint bonding, and chemical bonding, thermal bonding has distinct advantages. Wet bonding, for instance, is simpler and less expensive but lacks the precision and durability of thermal bonding. Wet bonding involves immersing fibers in a liquid adhesive, which is then cured to form a bond. However, this method is prone to warping and cracking, especially when dealing with thin or delicate materials.

Needlepoint bonding, another common technique, involves the use of needles to press fibers onto a backing material. While this method is more precise than wet bonding, it is also more time-consuming and labor-intensive. Chemical bonding, on the other hand, relies on the application of heat and pressure to cure a chemical adhesive. Although chemical bonding is similar to thermal bonding, it often requires more energy and can lead to higher production costs.

In contrast, thermal bonding offers a balance between precision and cost-effectiveness. It is particularly well-suited for producing nonwoven materials that require a high degree of uniformity and durability. While wet bonding and needlepoint bonding may be suitable for less demanding applications, thermal bonding is the preferred choice for industries that prioritize quality and performance.

Environmental Impact and Sustainable Practices in Thermal Bonding

The environmental impact of thermal bonding is a critical consideration in the nonwoven industry. While thermal bonding itself does not produce greenhouse gases, the process of heating and pressuring the materials can have an energy footprint. However, advancements in sustainable practices have addressed many of these challenges. For example, energy-efficient heating systems and the use of lower temperature settings have been adopted to reduce energy consumption.

Additionally, recycling and waste management are increasingly important in the nonwoven industry. Many manufacturers are implementing recycling programs to reduce the environmental impact of their operations. Thermal bonding plays a role in this process by enabling the precise bonding of materials that can be easily separated and recycled.

As the demand for sustainable products grows, so does the importance of minimizing the environmental impact of thermal bonding. By adopting energy-efficient practices and investing in recycling technologies, manufacturers can reduce their carbon footprint and contribute to a more sustainable future.

Applications of Thermal Bonding in Nonwovens

Thermal bonding has a wide range of applications in the nonwoven industry, making it a versatile and valuable technology. One of the most common uses of thermal bonding is in the production of medical-grade nonwovens. These materials are used in medical products such as bandages, dressings, and surgical gloves, which are essential for patient care. The durability and strength of nonwovens produced through thermal bonding make them ideal for these applications.

Another significant application of thermal bonding is in the filtration industry. Nonwoven filters are used in various sectors, including air purification, water treatment, and industrial filtration. Thermal bonding allows for the precise bonding of filter media, ensuring high efficiency and long lifespan. This makes thermal bonding a critical component of filtration systems that require reliability and performance.

Thermal bonding is also widely used in the production of hygiene products, such as towels and facial tissues. These products are essential for maintaining personal hygiene, and their effectiveness depends on the quality of the materials. Nonwoven products made through thermal bonding are known for their absorbency, softness, and durability, making them a popular choice in the hygiene industry.

In addition to these applications, thermal bonding is increasingly being used in the production of comfort goods, such as textiles and clothing. Nonwoven materials can be bonded to fabric or other materials to create hybrid products that combine the benefits of both. This is particularly useful in the textile industry, where thermal bonding can enhance the performance of fabrics in terms of comfort, durability, and weather resistance.

Future Trends in Thermal Bonding Technology for Nonwovens

The future of thermal bonding in the nonwoven industry is bright, with several emerging technologies and trends poised to shape the industry in the coming years. One of the most exciting developments is the use of advanced heating methods, such as infrared heating and vacuum degassing. These technologies allow for more precise control over the bonding process, resulting in higher quality materials with fewer defects.

Another trend is the integration of automation and robotics into thermal bonding processes. Automated systems can significantly increase production efficiency by reducing the need for human intervention. This not only speeds up the production process but also minimizes the risk of human error, leading to higher quality and more consistent products.

Sustainability is also a key focus for the thermal bonding industry. Manufacturers are increasingly adopting eco-friendly practices, such as energy-efficient heating systems and recycling programs, to reduce their environmental impact. Additionally, the development of biodegradable and recyclable nonwoven materials is gaining momentum, aligning with global efforts to reduce waste and promote sustainability.

In conclusion, thermal bonding is a vital technology in the nonwoven industry, driving innovation and enabling the production of high-quality materials for a wide range of applications. As the industry continues to evolve, advancements in automation, sustainability, and material science will further enhance the capabilities of thermal bonding, ensuring its continued relevance and importance in the years to come.

References

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co