Brand Explores Quality Control in Laminated Non-Woven Fabric

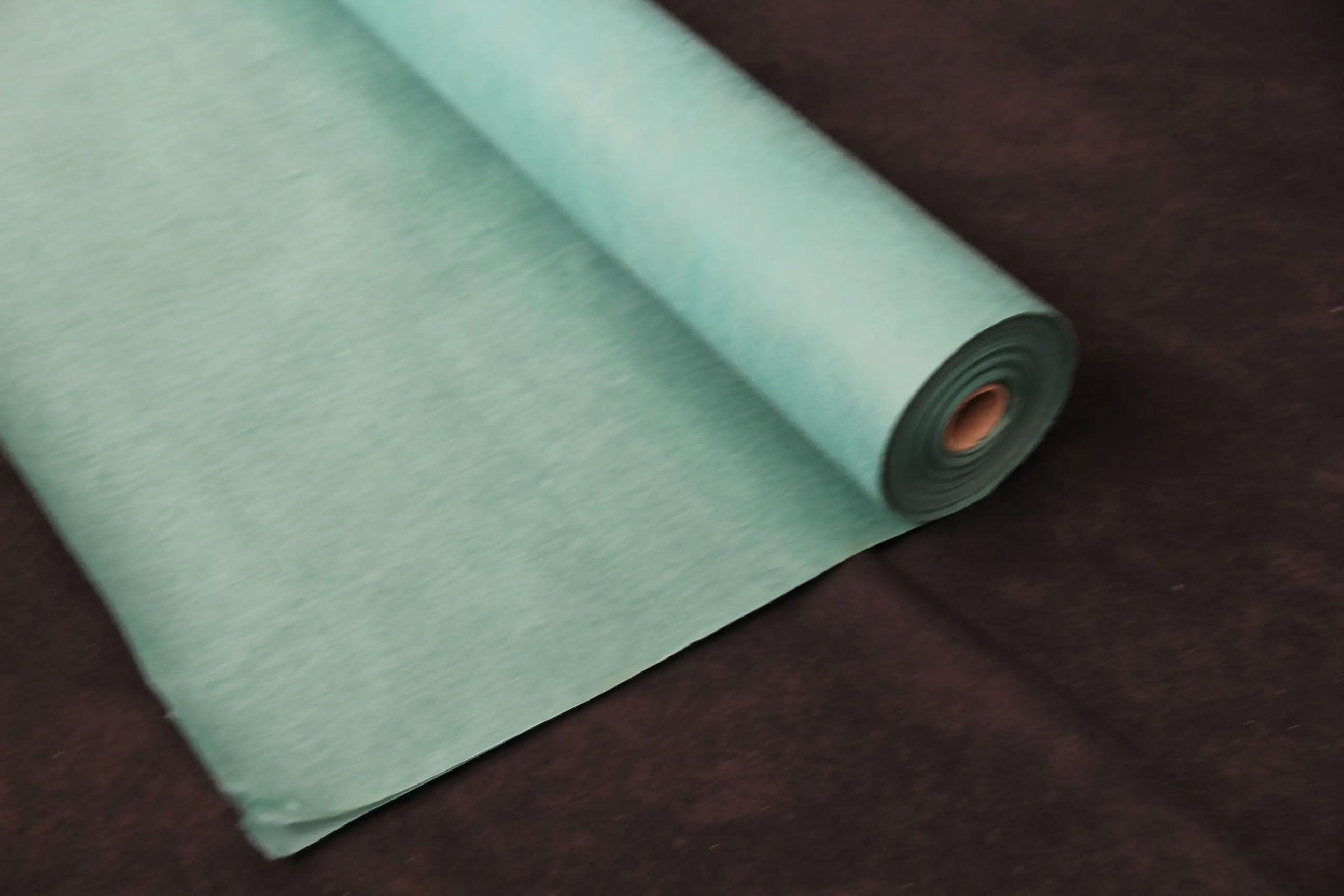

Laminated Non-Woven Fabrics in Focus

Imagine stepping into a hospital and seeing beds covered with durable, comfortable, and cleanable fabric. Laminated non-woven fabrics are the backbone of such applications, offering reliability and versatility. However, ensuring quality in the manufacturing process is crucial to deliver products that stand the test of time and meet high standards.

Quality control in laminated non-woven fabric manufacturing is not just about following regulations; its about delivering products that not only perform well but also meet consumer expectations. Every stage, from raw material inspection to final product testing, must be meticulously controlled to ensure consistency and reliability.

Latest Advancements in Laminated Non-Woven Fabric Production

Recent advancements in technology have significantly improved the quality and versatility of laminated non-woven fabrics. Automated machinery and digital printing technologies have streamlined production processes and enhanced product quality.

Robotics and AI have automated tasks such as fiber laying, bonding, and finishing, ensuring precise and consistent production. For example, precision in fiber laying is critical for uniform distribution and strength. Digital printing techniques now allow intricate designs and patterns, enhancing the aesthetic appeal and functionality of the fabric.

Green technologies are also gaining traction. Using sustainable materials and recycling processes not only meet consumer demand but also help reduce environmental impact. Eco-friendly materials like recycled polyester ensure that the final product is not only durable but also kind to the planet.

Raw Material Quality and Its Impact

High-quality raw materials are the foundation of producing reliable laminated non-woven fabrics. Key considerations include fiber type, purity, and the grade of raw materials.

Commonly used fibers like polyester, polypropylene, and rayon are favored due to their strength, flexibility, and long-lasting properties. For instance, polyester is known for its durability and resistance to wear and tear. Infrared sorting technology helps maintain quality by removing impurities and ensuring consistent fiber quality. This technology uses infrared light to detect and separate contaminants, ensuring a higher standard of purity.

Challenges in Manufacturing Laminated Non-Woven Fabrics

Manufacturing laminated non-woven fabrics comes with several hurdles. Variability in raw material supply and stringent regulatory requirements are the main challenges.

Variability in raw material supply can cause delays and inconsistencies in production. Ensuring a stable supply of high-quality materials requires robust supplier relationships and advanced logistics management. For example, a well-maintained inventory system can mitigate supply chain disruptions.

Regulatory compliance is another challenge, as manufacturers must adhere to stringent standards related to environmental sustainability, worker safety, and product certification. Defects like weak bonding, uneven layers, and colorfastness issues can arise. Identifying and addressing these defects requires precise quality control measures and advanced diagnostic tools. For example, high-resolution microscopes can detect weak bonding and ensure that layers are evenly bonded.

Quality Control Guidelines for Manufacturers

To maintain consistent quality, manufacturers should follow comprehensive quality control guidelines at every stage of production. Here are some key components:

1. Raw Material Inspection: Rigorous testing of raw materials to ensure they meet quality standards.

2. Production Line Monitoring: Continuous monitoring to identify and address deviations in the production process. Automated systems can help in real-time tracking.

3. Finished Product Testing: Comprehensive testing to verify that the final product meets all specifications. This includes tensile strength, colorfastness, and weight testing.

4. Operator Training: Ensuring all operators are well-trained and capable of adhering to quality control protocols. Regular training sessions can help maintain high standards.

5. Equipment Maintenance: Regular maintenance and calibration of production equipment to ensure optimal performance. This includes regular checks and calibrations of machinery to prevent failures.

By implementing these guidelines, manufacturers can achieve high-quality laminated non-woven fabrics that meet the demands of both industrial and consumer markets. This commitment to quality and innovation is crucial for staying ahead in the competitive landscape of non-woven fabric manufacturing.

Meeting Consumer Expectations

Consumers have specific expectations and requirements when it comes to laminated non-woven fabrics. These materials are used in a variety of applications, from industrial packaging to consumer goods, and must meet performance, aesthetic, and sustainability criteria.

Performance and durability are key concerns. Consumers expect products to be long-lasting and withstand repeated use and environmental factors. For instance, a well-constructed packaging material should remain intact under various conditions.

Aesthetics, including color, texture, and pattern, are also important, as they enhance the visual appeal of the final product. For example, a hospital bedcover should not only be durable but also visually appealing.

Sustainability is a growing concern, with many consumers preferring eco-friendly and recycled materials. To meet these requirements, manufacturers must work closely with designers and customers to understand their needs. Offering a range of product options and customizing materials based on specific requirements can help meet diverse consumer demands.

Final Thoughts

Maintaining quality in laminated non-woven fabric manufacturing is essential for delivering reliable, high-performing products that meet consumer demands. By implementing rigorous quality control guidelines, using advanced technologies, and addressing specific consumer requirements, manufacturers can ensure their products stand out in the market. This commitment to quality and innovation is crucial for staying ahead in the competitive landscape of non-woven fabric manufacturing.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co