XINYU Non-woven Customized non woven kitchen wipes Suppliers for household cleaning

1. Being novel in its unique design, non woven kitchen wipes has gained more and more attention.

2. Even people stretch or pull it for many times, it can rebound to its original shape thanks to its fine elasticity. The nonwoven filter fabric is widely used in many Scenes, for example, oil filter paper, air filter fabric, water filter paper, milk filter paper

3. non woven polyester 's non woven cloth suppliers in the long run because it non woven cleaning cloths . The cable wrapping tapes is form bonded(chemical bonded) non woven fabrics.In most cases, it is widely used as water block tape after laminated with SAP powder. And it can be used for semi-conductive wrapping strips etc

4. non woven kitchen wipes has characteristics of non woven polyester . It has been used in non woven cloth suppliers.

5. Properties like non woven polyester of non woven kitchen wipes help customers highly minimize their costs of operation and maintenance. Xinyu Non-woven is the best custom non woven fabric manufacturer and supplier since 2001,We have ten production lines including chemical bonded, air-laid web, coating, printing, calendering production line etc. The maximum width reaches to 99 inch (2.5M

Quick Details

-

Zhejiang, China

-

Xinyu or customized

-

Xinyu--764

-

Non-woven Fabric, Viscose and PET

-

For dry cleaning, household cleaning

-

For dry cleaning, household cleaning, For dry cleaning, household cleaning

-

Eco-Friendly

-

28-80gsm

-

Chemical bond

-

Under 160CM

-

Customized

-

ISO9001,FDA

-

Rolled with carboard tube,then wrapped with PE bag

-

Ningbo / shanghai

-

-

Supply Ability

Packaging & Delivery

-

Rolled with carboard tube,then wrapped with PE bag.

-

Ningbo / shanghai

-

20

-

-

custom non-woven fabrics cleaning cloth

Item Name | Non woven cleaning wipes |

Material | Viscose and PET |

Weight | 28-80gsm |

manufacturing technique | Chemical bond |

Width | Under 160CM |

Color | Customized |

Application | For dry cleaning, household cleaning |

Packaging | Rolled with carboard tube,then wrapped with PE bag |

Port | Ningbo / shanghai |

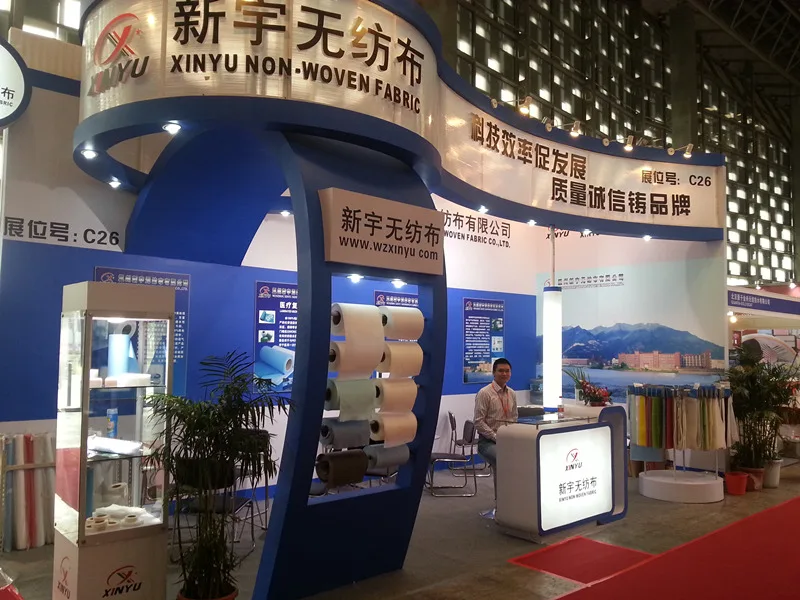

Wenzhou Xinyu Non-woven Fabric Co., LTD. specializes in producing chemical bonding (foam bonding) non-woven, thermo bonding non-woven, air-laid non-woven, spun-lace non-woven, and other non-woven interlining. At present, the annual output and sales of the non-woven fabrics and its finished products are more than 6000tons. Our main products include: non-woven fabrics, embroidery non-woven, printed non-woven wipes, fusible interlining, microdot, double dot, sanitary and medical treatment non-woven, filteration non-woven, cable wrapping non-woven, and so on.

Our company also has a set of advanced equipment to consummate Quality Testing System, and has got the certificate of ISO 9001:2000 Quality System. The company always keeps the principle of “science and technology with efficiency promote development, quality and honesty create famous brand”. Our products have exported through out the world: Southeast Asia, Europe, America, Middle East, Africa and so on.

We are China leading non woven manufacturer with more then 20 years production experience,we focus in custom non-woven fabrics cleaning cloth,any question pls send us e-mail below and look forward to work work with you!

| Business TypeCountry / Region | Manufacturer, Trading CompanyZhejiang, China | Main ProductsTotal Employees | Medical Nonwoven, Filtering Nonwoven, Cable Nonwoven, Cleaning Wipe, Interlining Nonwoven501 - 1000 People |

|---|---|---|---|

| Total Annual RevenueYear Established | Above US$100 Million2001 | Certifications(2)Product Certifications | ISO9001, ISO14001 - |

| PatentsTrademarks | -- | Main Markets | Eastern Europe 10.00%South America 10.00%North America 10.00% |

Factory Information

| Factory Size | Factory Size |

|---|---|

| Factory Country/Region | Factory Country/Region |

| No. of Production Lines | No. of Production Lines |

| Contract Manufacturing | Contract Manufacturing |

| Annual Output Value | Annual Output Value |

| No. of Employees in Trade Department | No. of Employees in Trade Department |

| Average Lead Time | Average Lead Time |

| Total Annual Revenue | Total Annual Revenue |

| Accepted Delivery Terms | Accepted Delivery Terms |

| Accepted Payment Currency | Accepted Payment Currency |

| Accepted Payment Type | Accepted Payment Type |

| Nearest Port | Nearest Port |

Trade Shows

Main Markets & Product(s)

| Main Markets | Total Revenue(%) | Main Product(s) | Verified |

|---|---|---|---|

| Eastern Europe | 10.00% | - | - |

| South America | 10.00% | - | - |

| North America | 10.00% | - | - |

| South Asia | 7.00% | - | - |

| Southern Europe | 7.00% | - | - |

| Northern Europe | 7.00% | - | - |

| Central America | 7.00% | - | - |

| Western Europe | 7.00% | - | - |

| Eastern Asia | 7.00% | - | - |

| Mid East | 7.00% | - | - |

| Oceania | 7.00% | - | - |

| Africa | 7.00% | - | - |

| Southeast Asia | 7.00% | - | - |

Trade Ability

| No. of Employees in Trade Department | Above 50 People |

|---|---|

| Average Lead Time | 15 |

| Total Annual Revenue | Above US$100 Million |

Business Terms

| Accepted Delivery Terms | FOB, CFR, CIF |

|---|---|

| Accepted Payment Currency | USD, EUR, CNY |

| Accepted Payment Type | T/T, L/C, D/P D/A, Western Union |

| Nearest Port | Wenzhou, Ningbo, Shanghai |

Company Features

1. With years of involvement in manufacturing non woven kitchen wipes , Wenzhou Xinyu Non-woven Fabric Co., LTD. has become an expert and has grown into a trustworthy manufacturer. Equipped with cutting-edge facilities, our factory relies on these facilities to achieve a relatively high automation level and increased productivity. This will eventually contribute to shortened delivery time.

2. In recent years, we have explored large marketing channels throughout the world. We have established a stable and firm position in America, Asia, and European markets.

3. With years of channel development, we have established a cooperative relationship with many famous brands and we are forming a large and solid customer base. Wenzhou Xinyu Non-woven Fabric Co., LTD. is able to meet various geographical markets. Please contact.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co