What Is PE Laminated Non-Woven Fabric?

Well folks, let's dive into the magical world of non-woven fabrics. The term may seem a little technical, but it's nothing you can't handle. So, what are non-woven fabrics, you ask? These are materials made from fibers held together by processes other than weaving, such as heat, chemicals, or pressure. The end result is a fabric with a unique set of properties, distinguishing it from traditional woven or knitted materials.

Born out of necessity during World War II, non-woven fabrics have come a long way. Initially created as a substitute for cotton which was in short supply, they've morphed into a staple component of numerous industries. Impressive, right? Let's take a look at some of the types of non-woven fabrics, which come in all shapes and sizes, just like we do.

What is PE Laminated Non-Woven Fabric?

Alright, let's get down to the star of our show, PE laminated non-woven fabric. Here we have a non-woven fabric that's been given a boost. It's kind of like when Peter Parker got bitten by that radioactive spider and turned into Spider-Man. It's still the same non-woven fabric, but it's been enhanced with some additional superpowers.

Definition of PE Laminated Non-Woven Fabric

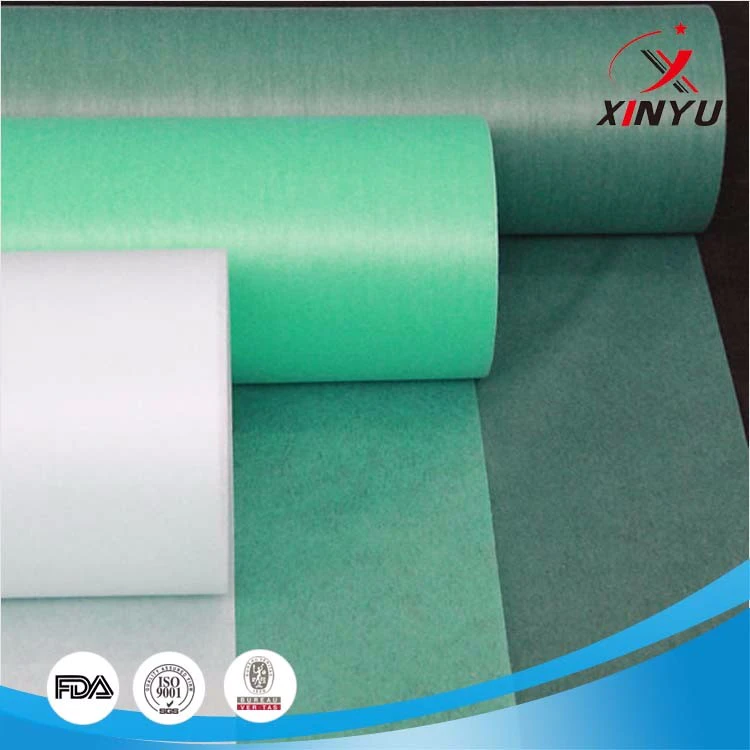

A PE laminated non-woven fabric is, in essence, a non-woven fabric that has been coated with a layer of PE, or polyethylene. This gives it a set of enhanced properties, making it ideal for certain applications.

Overview of PE (Polyethylene)

PE, or polyethylene, is one of the most commonly used plastics worldwide. It's durable, flexible, and most importantly for our purposes, waterproof. It's like a protective raincoat that shields our non-woven fabric from the elements.

Process of PE Lamination onto Non-Woven Fabric

The lamination process, which might sound like a technical dance move, is actually quite straightforward. It involves applying a thin layer of PE onto the non-woven fabric. This is usually done using heat and pressure. The result is a fabric that maintains the beneficial properties of a non-woven, but with added water resistance and durability.

Characteristics of PE Laminated Non-Woven Fabric

Now that we've introduced our main player, let's delve into what sets PE laminated non-woven fabric apart from the crowd.

Physical Properties

Physically speaking, PE laminated non-woven fabrics are like the athletes of the fabric world. They're strong, resilient, and incredibly light. Whether it's enduring high pressure or stretching without tearing, these fabrics are up to the task. But don't let their strength fool you - these materials are also lightweights.

Not in the derogatory sense, of course, but literally. They're light, making them easy to handle and transport.

Chemical Properties

On a chemical level, these fabrics are the James Bonds of the material world - unflappable in the face of various chemicals and able to handle heat like a pro. Their resistance to many common chemicals makes them a safe choice in many applications, and their tolerance for heat means they can withstand high-temperature sterilization, something crucial in the medical field.

Functional Properties

Functionally, these fabrics are a dream come true for many industries. Thanks to the PE layer, they're water-resistant, yet still breathable. It's like having an umbrella that keeps you dry in the rain but also lets the breeze through on a hot day. Can you think of anything better?

Benefits Of Using PE Laminated Non-Woven Fabric

You might be wondering why all this talk about PE laminated non-woven fabric matters to you. Well, the benefits of using this material are vast and touch upon many aspects of our lives. Let's take a look.

Advantages in Different Applications

Different sectors reap different rewards from using PE laminated non-woven fabric, showcasing the versatility of this material.

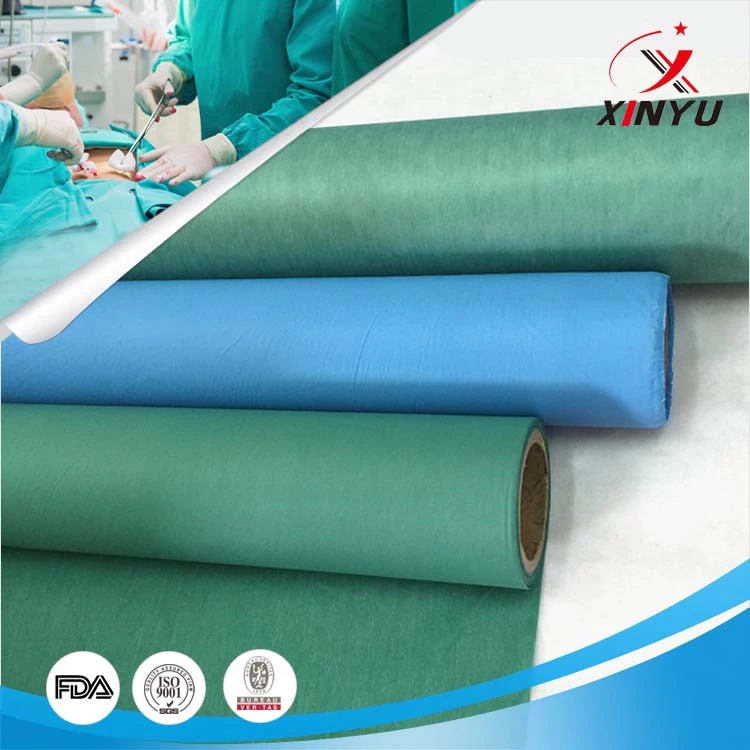

Medical Field

In the medical field, the fabric's strength, breathability, and water resistance make it ideal for protective garments and face masks, offering both comfort and protection to healthcare workers.

Packaging Industry

For the packaging industry, the durability and water resistance of this fabric is a boon. Whether it's wrapping up fresh produce or protecting electronics from moisture, this fabric has it covered.

Construction Industry

The construction industry also benefits, from using the fabric as a high-quality and cost-effective alternative to traditional materials for things like house wrap or insulation.

Cost-effectiveness

In terms of cost, PE laminated non-woven fabric offers a great bang for your buck. It provides superior performance and versatility at a lower cost than many traditional materials, making it an attractive option for businesses looking to trim expenses without compromising quality.

Environmental Impact

Now, I know what you're thinking - what about the environment? Well, you'll be glad to know that PE laminated non-woven fabric has a few green credentials. For starters, it's recyclable, meaning it can be turned into new products rather than ending up in landfill. Plus, the production process is relatively energy-efficient, contributing to its sustainability.

Conclusion

Well folks, we've journeyed through the ins and outs of PE laminated non-woven fabric and it's been quite the adventure, hasn't it? We've uncovered its roots in the versatile world of non-woven fabrics, dove into the transformative process of PE lamination, and explored the unique characteristics that make it stand out in the fabric lineup.

The versatility, resilience, and wide-ranging applicability of PE laminated non-woven fabric make it a material of great interest and potential. And while we've come to the end of our journey today, the exploration of this fabric's possibilities is just beginning.

So next time you come across a non-woven fabric, remember, it's more than just a material. It's a testament to human ingenuity and our relentless pursuit of innovation. Now that's something to appreciate.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co