Understanding the Working Principle of Wrapping Tape

Wrapping tape has evolved from its basic adhesive origins to more advanced and environmentally conscious solutions. Modern wrapping tapes now offer superior resistance to moisture and extreme temperatures, enhancing their durability in various applications. Advancements in sustainable production methods have introduced biodegradable and eco-friendly options, reducing the environmental footprint of shipping and packaging processes. The integration of smart technologies such as sensors and RFID tags is also transforming wrapping tape into a tool for enhanced supply chain management and real-time asset tracking. This combination of functionality, sustainability, and technology not only improves operational efficiency but also meets growing consumer expectations for eco-friendly products.

Types of Wrapping Tape and Their Properties

Heres a detailed guide to the various types of wrapping tapes and their properties:

- Fiberglass or Cloth Tape: Exhibits high tensile strength and resistance to environmental factors like humidity, making it ideal for securing heavy machinery and equipment in warehouses.

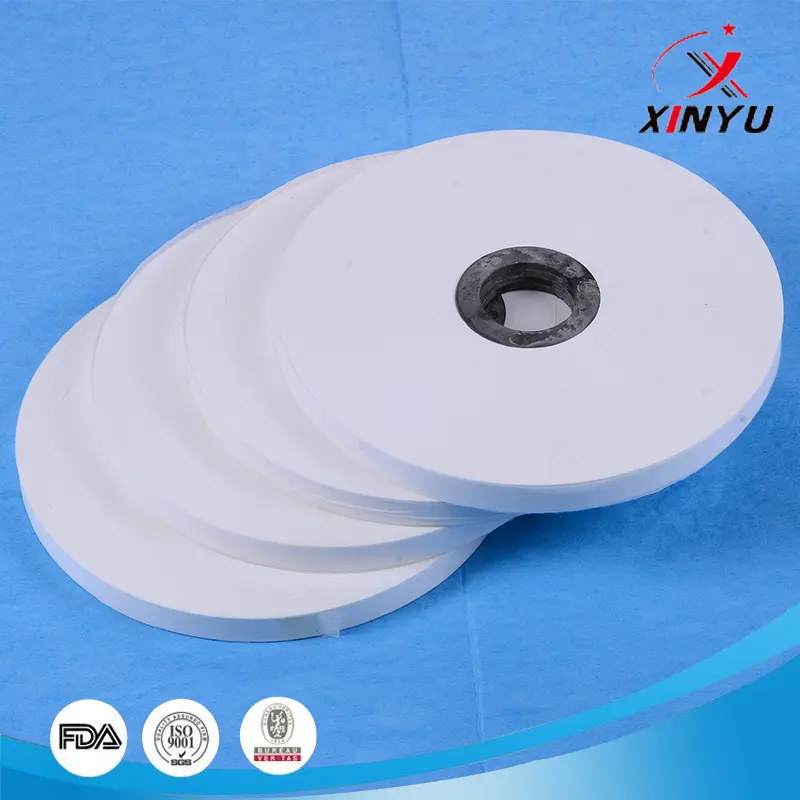

- PE (Polyethylene) Tape: Known for its flexibility and ease of application, this tape is suitable for shipping delicate or oddly shaped items, offering excellent moisture and chemical resistance.

- BOPP (Biaxially Oriented Polypropylene) Tape: Provides strong tensile strength and moisture resistance, making it a versatile choice for both warehouse management and shipping.

- Masking Tape: Designed for temporary packaging and securing smaller items, offering a straightforward and user-friendly application process.

- Heat-Activating Tape: Activates and strengthens when heat is applied, making it particularly useful for high-stress shipments, such as those involving high-value or important packages.

Wrapping Tape Applications Across Industries

Wrapping tape applications across various industries showcase the versatility of these materials in addressing specific challenges:

- Construction: Tapes designed for extreme temperatures and UV exposure are vital for roof repairs and siding, ensuring long-lasting and reliable performance.

- Electronics: Anti-static tapes play a crucial role in protecting sensitive components from static discharge, maintaining product integrity during handling and storage.

- Automotive: Moisture and chemical-resistant tapes are essential for vehicle components, while pharmaceuticals utilize moisture-resistant tapes to safeguard temperature-sensitive pharmaceuticals during transportation.

- Sustainability: The implementation of bio-based and recyclable tapes is growing, driven by sustainability goals that reduce environmental impact and enhance product performance. Collaborative efforts between industries often lead to innovative solutions, such as self-healing materials and smart sensor integration.

Environmental Considerations and Sustainability

The move towards sustainable solutions in packaging materials benefits the planet and aligns with global efforts to reduce waste. Eco-friendly wrapping tapes, such as those made from plant-based materials, recycled content, and bio-based polymers, represent significant advancements. However, the full transition requires addressing challenges such as higher costs, durability issues in harsh environments, and consumer awareness. Innovations in material science and manufacturing, coupled with smart technologies like sensors and advanced recycling, enhance sustainability. Effective urban planning, including smart bins and dedicated recycling facilities, and collaborative efforts between stakeholders contribute to a smarter and more sustainable urban environment.

Best Practices and Cost Efficiency in Wrapping Tape Usage

Best practices in wrapping tape usage focus on reducing waste, improving efficiency, and maintaining quality. Key challenges include inconsistent application and overestimation of required tape length, which can be mitigated through precise measuring techniques and proper tool usage. Automated tape dispensers and digital measuring apps ensure consistent application and precise cuts, minimizing waste. Integration into supply chain and quality control systems provides real-time data sharing, enhancing operational efficiency. Predictive maintenance systems further improve equipment performance, ensuring consistent and optimal tape dispensing. Sustainable practices involve adopting eco-friendly tapes made from recycled materials or biodegradable options, reducing environmental impact while maintaining quality.

Conclusion

Adopting eco-friendly and smart adhesives offers significant benefits in sustainability and performance. However, these materials are often hindered by initial costs and the need for robust testing protocols. Key performance criteria such as peel strength, water and temperature resistance, and non-toxicity are essential for reliability. Cost-effectiveness is achieved through strategic partnerships, grant applications, and public awareness campaigns. Consequently, integrating these innovative adhesives into local communities and businesses requires focused approaches on cost-sharing models and sustainable business practices to ensure they are accessible and economically viable at larger scales.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co