Nonwoven Fusible Interlining Enhances Garments

In the ever-evolving world of fashion, materials play a pivotal role in determining the quality, durability, and appeal of garments. Among the myriad options available, nonwoven fusible interlining has emerged as a game-changer, offering a blend of structural integrity and aesthetic appeal. This innovative material is gaining traction not only for its functional benefits but also for its eco-friendly alternatives, making it a cornerstone in contemporary fashion.

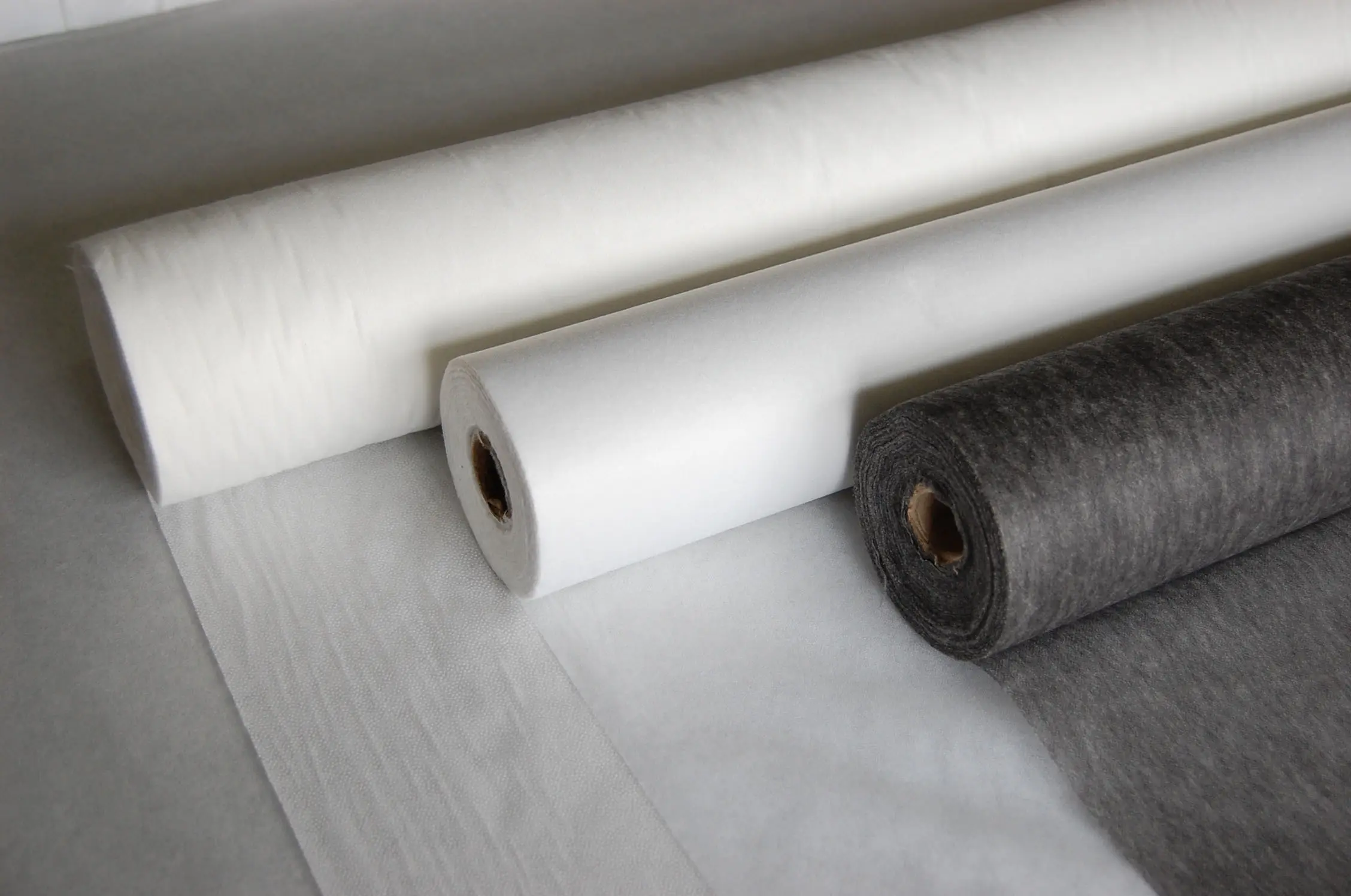

Nonwoven fusible interlining is a versatile material composed of nonwoven fibers that are bonded together and then fused with fabric using heat and pressure. This process imparts structural support, enhancing the drape and shape of garments. Unlike traditional interlinings, the fusible type can be easily sewn into fabrics, ensuring a seamless integration.

The manufacturing process involves layering nonwoven fibers, heating them to their melting point, and pressing them onto fabric. This method ensures durability and stability, making the material ideal for various garment applications. The flexibility of nonwoven fibers allows for intricate designs, contributing to the overall aesthetic of fashion pieces.

Benefits of Nonwoven Fusible Interlining

The adoption of nonwoven fusible interlining in garments offers several advantages. It significantly enhances garment stability, reducing fabric shifting during wear. Improved fit is another key benefit, as the interlining conforms to the body, offering a tailored look. Durability is also amplified, as the material resists wear and tear, ensuring longevity.

These benefits translate into higher consumer satisfaction, as garments with nonwoven fusible interlining are perceived as higher quality. Additionally, the material's ability to maintain shape during washing and wear ensures a consistent appearance, further enhancing the garment's value.

How Nonwoven Fusible Interlining Enhances Garment Quality

The role of nonwoven fusible interlining extends beyond stability and durability. It enhances drape by allowing fabric to flow naturally, creating a smooth and elegant look. The interlining also maintains shape, preventing fabric sagging or losing its form over time.

In terms of stitch stability, the interlining provides a secure base for stitching, reducing the risk of unraveling. This is particularly beneficial in high-volume production, where maintaining quality is paramount. The material's durability also reduces the need for frequent alterations, lowering maintenance costs for manufacturers.

Eco-Friendly Alternatives to Nonwoven Fusible Interlining

As sustainability becomes a priority in the fashion industry, eco-friendly alternatives to nonwoven fusible interlining are gaining attention. Bio-based materials, derived from agricultural waste or renewable resources, offer a greener option. These materials reduce the carbon footprint associated with traditional interlinings, aligning with global sustainability goals.

Recycling practices are also being explored to enhance environmental impact. By ensuring that nonwoven fusible interlining can be recycled or composted, the industry moves toward a more sustainable future. These practices not only benefit the environment but also contribute to consumer preferences for eco-conscious products.

Applications of Nonwoven Fusible Interlining in Fashion Industry

Nonwoven fusible interlining is integral to various garment types, from casual wear to formal attire. In sportswear, it enhances durability and shape, making it ideal for jackets, pants, and athletic garments. Shirts and tops benefit from enhanced stability and a professional appearance.

Coats and jackets, where shape retention is crucial, gain from the interlining's structural support. In upcycled garments, nonwoven fusible interlining serves as an effective lining, adding both style and functionality. Its versatility allows for creative applications, pushing the boundaries of traditional material usage.

Conclusion

Nonwoven fusible interlining is revolutionizing the fashion industry by offering a blend of structural integrity, durability, and aesthetic appeal. Its applications span across various garment types, ensuring quality and sustainability. As the industry embraces eco-friendly alternatives, nonwoven fusible interlining stands as a testament to innovation and environmental responsibility.

By understanding and utilizing nonwoven fusible interlining, manufacturers can produce garments that are not only stylish but also long-lasting and sustainable. This material represents a step forward in creating garments that meet modern standards of quality and environmental stewardship.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co