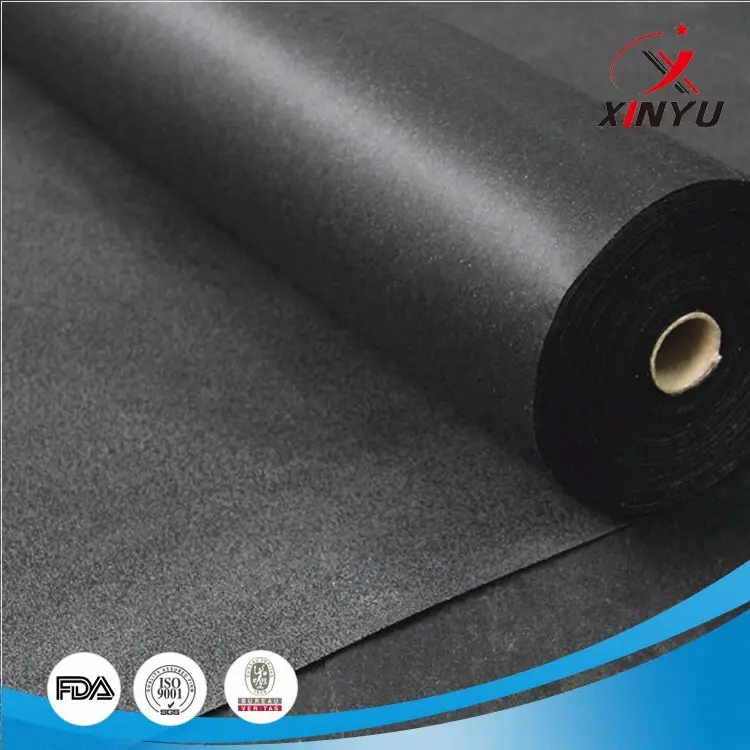

Insight into Nonwoven Fusible Interfacing

Nonwoven fusible interfacing is a versatile and valuable tool in garment construction, enhancing both the stability and professional appearance of fabrics. Produced by interlocking fibers through methods like needle-punching, hot-air bonding, and sonique bonding, each technique offers distinct advantages. Needle-punched interfacing is ideal for heavy materials like denim, providing strong support and durability, while hot-air bonded interfacing excels in delicate fabrics such as silk and chiffon, maintaining a sleek, drapey finish without adding bulk. Sustainability is increasingly important, with options like recycled polyester and natural fibers such as bamboo offering eco-friendly alternatives that reduce environmental impact. Choosing the right interfacing is crucial, balancing support and comfort while ensuring seamless integration into the design process and selecting materials that align with the garment's overall aesthetic.

Understanding the Benefits of Nonwoven Fusible Interfacing

Nonwoven fusible interfacing offers numerous benefits:

- Practicality - Provides quick and easy solutions for stabilizing fabrics and adding structure, enhancing the performance of various garment layers.

- Versatility - Offers diverse textures and weights, enabling designers to achieve unique and complex designs with precision.

- Sustainability - Many eco-friendly options exist, such as plant-based adhesives and interfaces that can be composted, reducing waste and environmental impact.

- Cost-effectiveness - Often uses less energy and water in production compared to woven or knit interfacing, making it a budget-friendly choice.

- Quality - Maintains top-notch performance without compromising on the quality of the end product, ensuring long-lasting durability and comfort.

Nonwoven Fusible Interfacing Manufacturing Processes

Nonwoven fusible interfacing manufacturing processes have evolved significantly, driven by innovation. Advanced fiber blends, such as those combining polyester, polypropylene, and cellulosic fibers, enhance strength, breathability, and thermal stability, while catering to sustainability preferences. Automation and robotics improve precision and reduce errors. Precision cutting machines and laser cutting technologies enable intricate designs and detailed cuts, while automated systems with machine learning implement real-time quality control. Additive manufacturing and 3D printing are used to create customized and complex structures, offering functional and aesthetic benefits that drive garment performance and customer satisfaction.

Application Examples and Design Considerations for Nonwoven Fusible Interfacing

Nonwoven fusible interfacing is widely used across various sectors, with unique design considerations:

- Delicate Fabrics (e.g., Silk) - Require finer and more pliable interfacing to maintain the natural drape and flow of the material.

- Heavy Fabrics (e.g., Denim) - Need firmer interfacing for stability and structure.

- Lightweight Fabrics (e.g., Chiffon) - Call for sheer interfacing to support the material while preserving its delicate appearance.

- Leather Goods - Demand heat-resistant interfacings to ensure stability during manufacturing and durability.

Challenges and Best Practices in Working with Nonwoven Fusible Interfacing

Challenges in working with nonwoven fusible interfacing include heat sensitivity, adhesion issues, and stiffness. Addressing these requires appropriate heat settings and pressing techniques:

- Use lower heat settings and shorter pressing times to prevent bubbling and melting.

- Employ a pressing cloth for heat-sensitive fabrics to further protect them.

- Pre-treat fabrics with steam to enhance heat resistance.

- Use sustainable and high-quality interfacing options from eco-friendly brands.

- When interfacing challenging fabrics like wool, denim, and stretch materials, test on a small sample and layer and place the interfacing thoughtfully to balance support and comfort.

Sustainability and Impact of Nonwoven Fusible Interfacing

Sustainability and impact of nonwoven fusible interfacing have gained attention in the fashion industry. These materials offer efficiency and waste reduction compared to traditional methods, favored in ready-to-wear and mass production. Biodegradable or recyclable materials enhance sustainability. Lifecycle assessments play a crucial role in understanding the environmental impact, guiding manufacturers towards sustainable practices. Collaboration among material suppliers, manufacturers, and brands is essential for advancing sustainability, driving innovation, and setting industry benchmarks. Technological advancements, such as 3D printing and smart, biodegradable materials, offer opportunities for more eco-friendly and efficient products. Regulatory compliance involves adhering to standards like Oeko-Tex and ASTM, which guide manufacturers in promoting safety and environmental stewardship.

Regulatory Requirements & Certification Processes

Ensuring the safety and quality of nonwoven fusible interfacing requires adherence to regulatory requirements and certification processes. Compliance with standards like Oeko-Tex and ASTM ensures consumer safety and sets benchmarks for sustainability. While these regulations can be costly for small and medium-sized enterprises (SMEs), they offer valuable guidance through support mechanisms like training programs. Effective strategies include staying informed about regulatory changes, implementing best practices, conducting regular internal audits, and seeking legal support to ensure continuous compliance.

FAQs Related to Nonwoven Fusible Interfacing

What are the main benefits of nonwoven fusible interfacing?

Nonwoven fusible interfacing provides practicality by offering quick and easy solutions for stabilizing fabrics and adding structure. It is versatile, with diverse textures and weights that enable designers to achieve unique designs. Additionally, many eco-friendly options are available, reducing waste and environmental impact. It is also cost-effective, uses less energy and water in production, and maintains high-quality performance without compromising the end product's durability and comfort.What manufacturing processes are used to produce nonwoven fusible interfacing?

Nonwoven fusible interfacing is manufactured through processes like needle-punching, hot-air bonding, and sonique bonding. Needle-punched interfacing is ideal for heavy materials, hot-air bonded interfacing for delicate fabrics, and sonique bonding for achieving specific properties. Advanced fiber blends, automation, 3D printing, and smart, biodegradable materials are also being used to enhance the technology.In what types of garment fabrics can nonwoven fusible interfacing be used?

Nonwoven fusible interfacing can be used in various types of fabrics, tailored to their specific needs. Delicate fabrics like silk require finer and more pliable interfacing to maintain their natural drape, while heavy fabrics like denim need firmer interfacing for added support. Lightweight fabrics like chiffon and leather goods benefit from specific types of interfacing that balance support and comfort.What are some challenges faced when using nonwoven fusible interfacing in garment construction?

Challenges include heat sensitivity, adhesion issues, and stiffness. To address these, designers should use lower heat settings, employ pressing cloths, and pre-treat fabrics with steam. Specific attention is required for interfacing heat-sensitive materials like wool, denim, and stretch materials, where testing on small samples and strategic layering are essential.What legal and regulatory requirements must be met for nonwoven fusible interfacing products?

Nonwoven fusible interfacing must comply with standards like Oeko-Tex and ASTM to ensure safety and quality. Regulatory compliance can be costly for small and medium-sized enterprises (SMEs) but offers valuable guidance through training programs and support mechanisms. Regular internal audits and seeking legal support are recommended to ensure continuous compliance with regulatory requirements and certification processes.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co