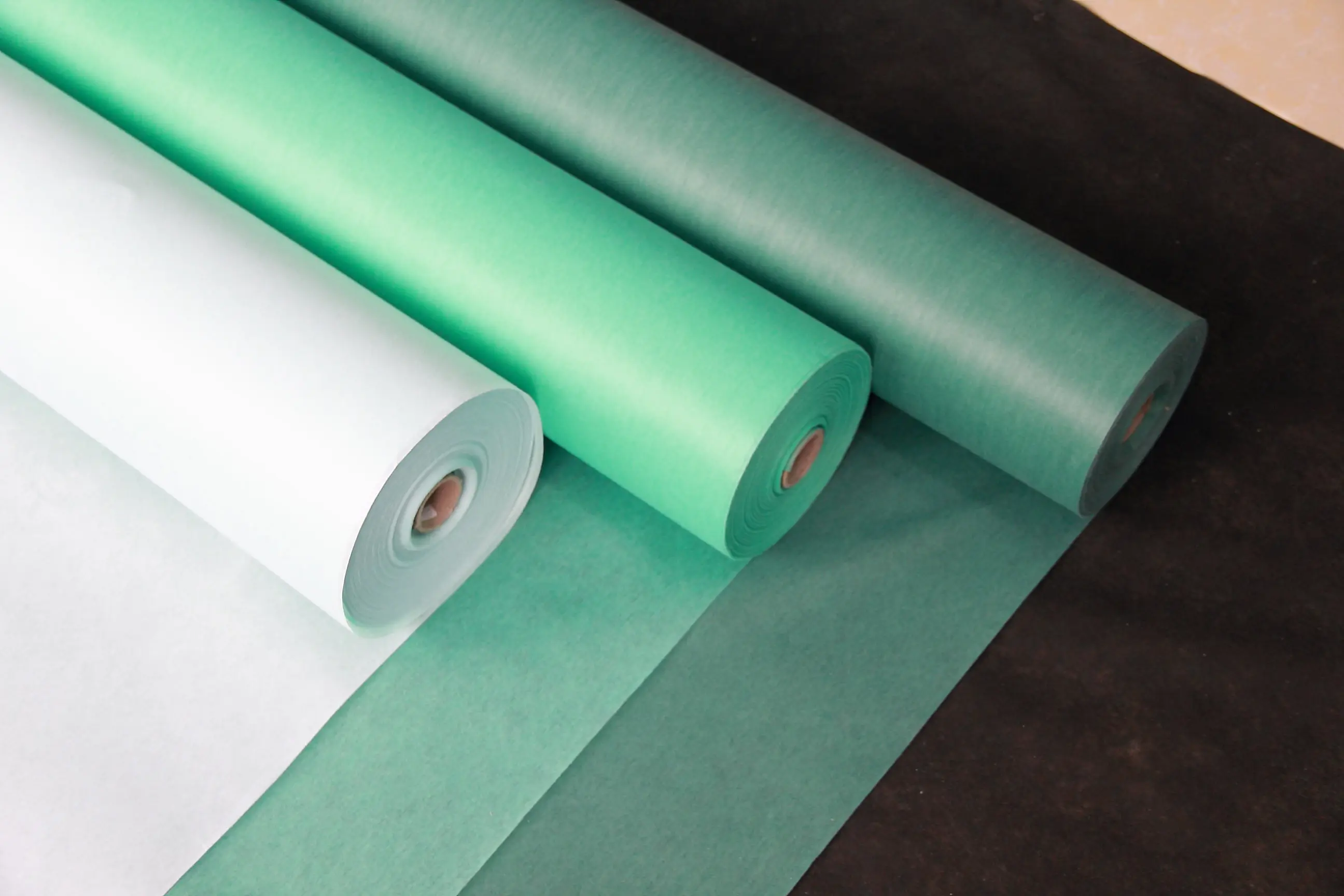

Hygiene Standards vs Comfort in Medical Non-Woven Fabrics

Medical non-woven fabrics have become an indispensable component in the medical industry, owing to their unique properties such as breathability, flexibility, and ease of use. These fabrics are designed to balance critical requirements of hygiene and patient comfort, often made from materials like polypropylene, polyethylene, and composites, often enhanced with hydrophilic substances to improve moisture management. Industry standards such as ISO 11607 and ASTM provide essential guidelines to ensure that the fabrics meet both regulatory and practical needs. Innovations such as nanotechnology, composite fabrics, and natural-based antimicrobial agents are increasingly being explored to meet the sustainable and effective demands of the medical products sector. These advancements not only enhance hygiene standards but also offer enhanced patient comfort and reduce environmental impact.

Hygiene Standards for Medical Non-Woven Fabrics

Hygiene standards are critical in medical non-woven fabrics, ensuring the safety and well-being of patients and healthcare professionals. High-quality materials such as polypropylene and spandex, combined with strict industry guidelines like ISO and ASTM, are essential for rigorous testing and quality control. Innovations, such as the incorporation of antimicrobial agents, moisture-wicking properties, and advanced nanotechnology, further enhance the hygiene and comfort of these materials. These advancements address the practical needs of medical facilities and the comfort requirements of patients, making the fabrics more acceptable and effective in real-world applications. Sustainable materials and practices, such as the use of bio-based fibers and recycled polypropylene, minimize the environmental impact without compromising hygiene and comfort.

Comfort in Medical Non-Woven Fabrics

Medical non-woven fabrics have increasingly focused on achieving a balance between hygiene standards and comfort. This is particularly important in critical applications such as personal protective equipment (PPE) and wound care garments. Advanced technologies, such as nanotechnology, improved antimicrobial properties, and breathable fibers, enhance the comfort of these materials. Smart textiles that incorporate moisture-wicking and thermal regulation features help maintain a comfortable microclimate on the skin, thereby enhancing both hygiene and patient satisfaction. Eco-friendly and biodegradable materials, like lyocell and bamboo-derived cellulose, are also being utilized to reduce the environmental impact of these textiles while maintaining performance levels. These advancements address the immediate needs of healthcare workers and patients, contributing to a more sustainable healthcare ecosystem.

Applications and Uses of Medical Non-Woven Fabrics

Medical non-woven fabrics are indispensable in various healthcare applications, due to their properties that combine hygiene and comfort. These fabrics are widely used in surgical environments, wound care, and personal protective equipment (PPE). In surgical contexts, they provide a sterile and durable barrier that withstands repeated sterilization processes, crucial for preventing healthcare-associated infections. For wound care, these fabrics must balance moisture management with antimicrobial properties to promote healing without causing maceration. Advances such as nano-composite materials and micro-channel technology have significantly improved the efficacy and comfort of these fabrics. These innovations enhance performance, focusing on sustainability by incorporating eco-friendly materials and developing recycling methods that can turn waste into valuable resources, thus optimizing the use of these fabrics for improved patient outcomes and reduced environmental impact.

Innovations and Challenges in Medical Non-Woven Fabrics

Innovations in medical non-woven fabrics, especially the integration of biodegradable polymers such as polylactic acid (PLA), have significantly advanced the field by offering sustainable solutions. However, these advancements come with notable challenges, including the need to balance hygiene standards and patient comfort. To address moisture management, engineers are exploring techniques such as electrospinning to create nanofibers and incorporating hydrophilic additives, although these approaches can increase production costs and complexity. Enhancing the mechanical properties of these materials without compromising moisture management and biodegradability is another critical issue. Composite materials and bio-based reinforcements, such as cellulose nanofibrils, have shown promise but require careful formulation to maintain cost-effectiveness and regulatory compliance. Leveraging emerging technologies like artificial intelligence and machine learning can streamline the regulatory approval process and production workflow, although data quality and system integration pose significant challenges. Real-time monitoring through AI and ML facilitates predictive maintenance and dynamic process adjustments, ensuring continuous improvement and optimal performance. Lifecycle analyses using tools like SimaPro or gaBi offer comprehensive insights into the environmental impact, guiding further sustainability improvements in these innovative materials.

Patient Advocacy on Comfort in Medical Fabrics

Patient advocacy plays a pivotal role in ensuring medical fabrics prioritize patient comfort, which significantly impacts healing and overall well-being. Efforts to enhance fabric comfort often involve developing and disseminating compelling case studies that demonstrate the tangible benefits of soft, breathable materials on patient outcomes. For instance, the use of more comfortable fabrics in hospitals can lead to reduced skin issues and improved patient satisfaction, as evidenced by successful implementations at institutions like Walter Reed National Military Medical Center. Furthermore, involving patients directly in the design and selection process through patient-focused committees can provide invaluable insights and ensure that the needs of patients are genuinely considered. By integrating patient feedback with robust clinical research, healthcare institutions can make informed decisions that not only enhance patient comfort but also improve medical outcomes.

FAQs Related to Medical Non-Woven Fabrics

What are the key properties of medical non-woven fabrics that balance hygiene and comfort?

Medical non-woven fabrics possess properties like breathability, flexibility, and ease of use, which are essential for maintaining hygiene while ensuring patient comfort. These fabrics are often made from materials such as polypropylene, polyethylene, and composites, which may be enhanced with hydrophilic substances to improve moisture management and comfort.What industry standards ensure that medical non-woven fabrics meet both regulatory and practical needs?

Industry standards such as ISO 11607 and ASTM provide essential guidelines for ensuring that medical non-woven fabrics meet regulatory and practical needs. These standards help in the rigorous testing and quality control of these fabrics to ensure they are safe and effective for use in medical settings.How do advancements in nanotechnology and composite fabrics enhance the effectiveness and comfort of medical non-woven fabrics?

Advancements in nanotechnology and composite fabrics significantly enhance the effectiveness and comfort of medical non-woven fabrics. These innovations incorporate antimicrobial agents, moisture-wicking properties, and advanced nanotechnology, which not only improve hygiene but also offer enhanced patient comfort and reduce environmental impact. They contribute to a more sustainable healthcare ecosystem while maintaining the necessary performance levels.What are some sustainable materials and practices used in the production of medical non-woven fabrics?

Sustainable materials and practices used in the production of medical non-woven fabrics include the use of bio-based fibers and recycled polypropylene. These materials minimize the environmental impact without compromising hygiene and comfort. Eco-friendly and biodegradable materials like lyocell and bamboo-derived cellulose are also being utilized to further reduce the environmental footprint while maintaining performance levels.How do patient advocates contribute to the prioritization of patient comfort in medical non-woven fabrics?

Patient advocates play a pivotal role in ensuring that medical non-woven fabrics prioritize patient comfort. They do this by involving patients directly in the design and selection process, often through patient-focused committees. Patient advocates also disseminate compelling case studies that demonstrate the tangible benefits of soft, breathable materials on patient outcomes, thereby ensuring that the needs of patients are genuinely considered and met in medical settings.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co