Expert Opinion on Fusible Lining Composition

The world of garment construction is constantly evolving, driven by the need for innovation and sustainability. One area where this evolution is evident is in the use of interliningstextures or materials inserted between layers of fabric to enhance the final product. Among the two main types of interlinings, fusible and non-fusible, each has its unique advantages and applications. Understanding the differences between these two can help manufacturers and designers make informed decisions about which to use in their projects.

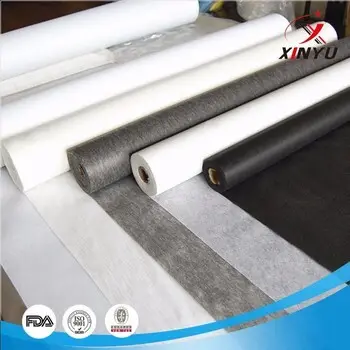

Introduction to Fusible and Non-Fusible Interlinings

Interlinings play a crucial role in garment construction, serving various purposes such as improving durability, enhancing aesthetic appeal, and managing moisture. They are typically made from materials like metallic powders, glass fibers, or synthetic polymers. The choice between fusible and non-fusible interlinings depends on the specific requirements of the garment.

Fusible interlinings are designed to be sewn directly into the fabric without the need for additional steps like ironing or pressing. They are often used for dimensional stability, such as in stretch knits or moisture-wicking fabrics. On the other hand, non-fusible interlinings are sewn separately and require a separate process to fuse them into the fabric.

The key difference between the two lies in their interaction with sewing machines and machinery. Fusible interlinings are easier to handle because they bond seamlessly with the fabric, while non-fusible interlinings require extra care to ensure they are properly aligned and fused.

Advantages and Limitations of Non-Fusible Interlinings

Non-fusible interlinings offer several advantages, particularly in terms of fabric texture and design flexibility. By sewing them directly onto the fabric, they maintain the original texture and feel of the fabric, which can be crucial for items like scarves, shawls, or lightweight fabrics. This makes them ideal for designs that require precision stitching or intricate patterns.

One of the main limitations of non-fusible interlinings is the need for careful application. Since they are sewn separately, they must be aligned precisely to ensure a smooth finish. This can be challenging, especially for complex or irregular designs. Additionally, non-fusible interlinings often require additional steps in the manufacturing process, which can increase costs.

Techniques and Best Practices for Using Non-Fusible Interlinings

To make the most of non-fusible interlinings, it is essential to follow proper techniques and best practices. First, pre-stitching the interlining onto the garment can help ensure accuracy and reduce stress on the machine. This involves sewing the interlining onto a temporary fabric that mimics the garment's structure before transferring it to the actual fabric.

Another important consideration is the type of machine being used. Some machines require special settings or adjustments to accommodate non-fusible interlinings. Paying attention to these details can help ensure a professional finish. Additionally, testing the interlining on a small sample can provide valuable insights into how it will perform in the final product.

Comparison Between Fusible and Non-Fusible Interlinings

The comparison between fusible and non-fusible interlinings is multifaceted. In terms of process, fusible interlinings are generally easier to handle because they bond directly to the fabric. This eliminates the need for additional steps like ironing or pressing, making the manufacturing process more efficient.

However, non-fusible interlinings offer greater design flexibility, allowing for more intricate patterns and textures. This makes them a popular choice for high-end fashion and artisanal textiles.

When it comes to cost, fusible interlinings can be more economical because they reduce the need for additional machinery and processes. On the other hand, non-fusible interlinings may have higher initial costs due to the complexity of their production.

In terms of environmental impact, fusible interlinings often involve more resource-intensive production processes, including the use of harmful chemicals. Non-fusible interlinings, while also requiring energy-intensive manufacturing, are generally more sustainable because they reduce waste generated during the fusion process.

Advantages and Sustainability of Fusible Lining

Fusible lining offers several advantages, particularly in terms of production efficiency and design flexibility. Since they are sewn directly into the fabric, fusible interlinings reduce the need for additional steps, which can lower production costs. They are also ideal for garments that require dimensional stability, such as stretch knits or moisture-wicking fabrics.

In addition, fusible interlinings can contribute to a more sustainable future by reducing waste generated during the fusion process. By fusing the interlining into the fabric in one step, they minimize the need for separate materials and processing steps.

Innovations in the production of fusible interlinings are also making a significant impact. For example, eco-friendly options are becoming more available, and some manufacturers are working to reduce waste and energy consumption. These advancements are helping to make fusible interlinings more sustainable without sacrificing quality.

Best Practices for Using Fusible Lining

Selecting the right fusible lining for a garment is crucial to achieving the desired result. Before purchasing, it is important to consider the type of fabric and the intended use of the garment. For example, fusible interlinings made from metallic powders are ideal for maintaining dimensional stability, while those made from glass fibers are better suited for moisture-wicking applications.

When it comes to handling fusible interlinings, proper care is essential. Machine settings and needle positions must be adjusted to accommodate the interlining, and the machine should be run at a lower speed to prevent damage. Testing the interlining on a small sample can also help ensure it will perform well in the final product.

Choosing the Right Interlining

Choosing the right interlining for your garment is a critical decision that can impact both the quality and sustainability of the final product. While fusible interlinings offer production efficiency and design flexibility, non-fusible interlinings provide greater design control and aesthetic appeal.

In today's world, sustainability is a key consideration, and non-fusible interlinings may offer a more eco-friendly alternative. However, the choice ultimately depends on the specific requirements of your project. Whether you prioritize efficiency, design, or sustainability, understanding the differences between fusible and non-fusible interlinings will help you make an informed decision.

By carefully considering the advantages and limitations of each type of interlining, you can select the right option for your garment and contribute to a more thoughtful and sustainable fashion industry.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co