The Difference Between Common Non-woven and Medical Non-woven

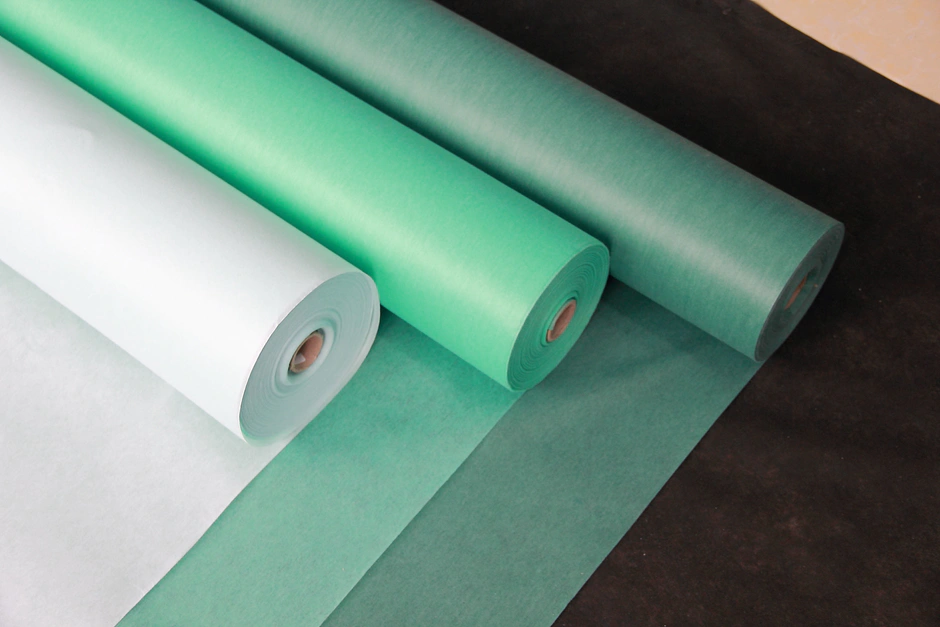

Non-woven fabrics available in the market are predominantly of two types: standard non-woven fabrics and medical non-woven fabrics. The latter used extensively in healthcare settings, adhere to rigorous quality standards due to their critical application in medical environments. Understanding the distinctions between these two types is essential.

Medical non-woven fabric is unique in its manufacturing process. Unlike traditional fabrics, it doesn't require spinning or weaving. Instead, it's formed by physically bonding materials, creating a fabric where threads cannot be unraveled. This process marks a departure from conventional textile methods. Medical non-woven fabrics offer several benefits over traditional cotton woven textiles. They are moisture-resistant, breathable, flexible, lightweight, non-flammable, biodegradable, non-irritating, cost-effective, and recyclable.

These attributes make them exceptionally suited for medical applications. Despite their widespread use and distinct features, many people find it challenging to differentiate medical non-woven fabrics from standard ones. This article aims to clarify these differences, providing a better understanding of each fabric type.

Versatile Antivirus Approaches in Medical Non-Woven Fabrics

Superior medical non-woven fabrics are designed to be compatible with multiple antivirus methods. Ideally, they should accommodate the pressure steam, ethylene oxide, and hydrogen peroxide methods. This multi-faceted approach contrasts with regular non-woven fabrics, which typically do not undergo such extensive disinfection processes.

Effectiveness in Antivirus of Medical Non-Woven

The construction of medical non-woven fabrics often involves a three-layer SMMMS meltblown structure, which enhances their antiviral capabilities. This is a step up from the standard industry practice of using a single-layer SMS melt-blown structure in common medical non-woven fabrics. The three-layer configuration significantly outperforms the single-layer in terms of antitoxicity. Non-medical non-woven fabrics, lacking a melt-blown layer, do not offer this level of antiviral effectiveness.

Environmental Friendliness of Medical Non-Woven

High-quality medical non-woven fabrics typically use PP (polypropylene) environmental protection particles. They are expected to comply with health and toxicology standards, often substantiated by relevant reports. Conversely, ordinary non-medical, non-woven fabrics may not be as resilient under high humidity conditions and are not usually subjected to the same level of toxicological scrutiny. This distinction underscores the environmentally conscious and safe nature of medical non-woven fabrics.

Rigorous Quality Control in Medical Non-Woven Fabric Production

Stringent standards, including adherence to the ISO13485 international medical product quality management system certification, govern the manufacturing of high-quality medical non-woven fabrics. Every stage of the production process undergoes real-time online inspections. This ensures that each batch of non-woven fabric is meticulously checked and accompanied by a corresponding inspection report before it leaves the production line. In contrast, standard non-medical non-woven fabrics are not subject to these rigorous medical-grade tests.

When it comes to purchasing medical non-woven fabrics, it's crucial to select a reputable manufacturer. This choice can prevent the risk of acquiring inferior quality products that could lead to economic losses or compromise safety.

Medical non-woven fabrics must conform to certain quality control systems' certifications. There are exacting standards and requirements for each phase of their production process. This level of quality control is one of the primary differentiators between medical non-woven fabrics and their non-medical counterparts.

Antibacterial Properties

A key feature of medical non-woven fabric is its antibacterial capability. This is typically achieved through a three-layer SMS melt-blown structure, which is more effective compared to the single-layer melt-blown structure used in ordinary medical non-woven fabrics. Non-medical non-woven fabrics, lacking a melt-blown layer, inherently do not possess antibacterial properties.

Kinds of Non Woven Fabric For Medical Use

Non-woven fabrics have become integral in medical applications due to their versatility and effectiveness. Here are some common types used in the medical field:

● Spunbond Nonwoven Fabric: This type of nonwoven fabric is produced by spinning continuous filaments of materials like polypropylene or other synthetic fibers. These fibers are then thermally bonded to form the fabric. Spunbond nonwoven fabric is known for its strength, breathability, and good barrier properties. These characteristics make it a popular choice for manufacturing medical gowns, drapes, and masks, where both protection and comfort are crucial.

● Meltblown Nonwoven Fabric: Meltblown Nonwoven Fabric: Hot air or steam is blown through a fine mesh screen to generate a web of fine microfibers. This fabric is ideal for surgical masks, filters, and other particle-filtration applications due to its absorbency and barrier qualities.

● SMS (Spunbond-Meltblown-Spunbond) Nonwoven Fabric: SMS nonwoven fabric is an advanced composite material that synergizes the properties of spunbond and meltblown fabrics. The outer spunbond layers impart strength and durability, while the inner meltblown layer enhances barrier properties and absorbency. This combination makes SMS nonwoven fabric a go-to choice for surgical gowns, drapes, and other types of medical protective clothing, providing both protection and comfort.

● Needle-Punched Nonwoven Fabric: The mechanical technique of connecting fibers with needles creates needle-punched nonwoven fabric, which is strong and absorbent. This fabric structure is ideal for wound dressings and bandages, which need durability and fluid absorption.

● Hydroentangled Nonwoven Fabric: The production of hydroentangled nonwoven fabric involves entangling fibers using high-pressure water jets. This innovative process yields a fabric that combines excellent strength and durability with softness and absorbency. Its unique qualities make it ideal for applications such as medical wipes and surgical drapes, where both gentleness and functionality are required.

Wenzhou Xinyu manufactures a variety of non-woven textiles. We customize non-woven textiles to your width, color, and specs. Our textiles may also be treated to offer hydrophilicity, anti-aging, anti-static, and UV protection, expanding their usage. Contact us for information.

Office Add: Shatou Industrial Area, Linjiang,

Tengqiao Town, Lucheng District, Wenzhou City,

Zhejiang Province, China.

Contact Us

Contact Person: Angle

Tel: +86-577-56976991

E-mail: xya@wzxinyu.com

Skype / Wechat: +86-13780146870

Contact Person: Suzie

Tel: +86-577-56976979

E-mail: xy03@wzxinyu.co